1. Isingeniso ku-Electric Motors

Injini kagesi iyisisetshenziswa esiguqula amandla kagesi abe amandla emishini.Isebenzisa ikhoyili enamandla (okungukuthi i-stator winding) ukuze ikhiqize inkambu kazibuthe ezungezayo futhi isebenze kurotha (njengekheji yengwejeje evaliwe ye-aluminium ifreyimu) yakhe itorque kamagnetoelectric ejikelezayo.

Amamotho kagesi ahlukaniswe ama-DC motors kanye nama-AC motors ngokuya ngemithombo yamandla ehlukene esetshenzisiwe.Iningi lama-motor ohlelweni lwamandla ama-AC motors, angaba amamotho ahambisanayo noma ama-asynchronous motors (isivinini se-stator magnetic field ye-motor asigcini isivinini esivumelanayo nesivinini sokujikeleza kwe-rotor).

Injini kagesi ikakhulukazi iqukethe i-stator ne-rotor, futhi isiqondiso samandla asebenza ocingweni olunamandla endaweni kazibuthe sihlobene nesiqondiso samanje kanye nesiqondiso somugqa wokungeniswa kazibuthe (isiqondiso sensimu kazibuthe).Umgomo wokusebenza kwenjini kagesi umphumela wenkambu kazibuthe kumandla asebenza kumanje, okubangela ukuthi injini ijikeleze.

2. Ukuhlukaniswa kwezinjini zikagesi

① Ukuhlelwa ngokusebenza kwamandla kagesi

Ngokusho kwemithombo yamandla asebenzayo ahlukene wamamotho kagesi, angahlukaniswa abe ama-DC motors nama-AC motors.Amamotho e-AC nawo ahlukaniswe amamotor esigaba esisodwa kanye namamotho ezigaba ezintathu.

② Ukuhlukaniswa ngesakhiwo kanye nesimiso sokusebenza

Amamotho kagesi angahlukaniswa abe ama-DC motors, ama-asynchronous motors, nama-synchronous motors ngokuya ngesakhiwo sawo kanye nesimiso sokusebenza.Amamotho e-synchronous angabuye ahlukaniswe abe amamotho kazibuthe avumelanayo ahlala njalo, amamotho avumelanayo angavumiyo, namamotho e-hysteresis synchronous.Ama-asynchronous motors angahlukaniswa abe ama-induction motors kanye nama-AC commutator motors.Izinjini zokungeniswa ziphinde zihlukaniswe zibe yizinjini ze-asynchronous ezinezigaba ezintathu kanye nama-asynchronous motors ane-shaded pole.Ama-motor we-AC Commutator nawo ahlukaniswe amamotor ajabulile esigaba esisodwa, ama-AC DC anenhloso ekabili, namamotho anyanyekayo.

③ Kuhlukaniswa ngemodi yokuqalisa nokusebenza

Amamotho kagesi angahlukaniswa abe amamotor e-capacitor aqalwe isigaba esisodwa asynchronous motors, capacitor esebenza isigaba esisodwa se-asynchronous motors, i-capacitor iqale amamotor asynchronous esigaba esisodwa, futhi ihlukanise isigaba esisodwa sesigaba esisodwa se-asynchronous motors ngokuya nezindlela zabo zokuqala nokusebenza.

④ Ukuhlukaniswa ngenhloso

Izinjini zikagesi zingahlukaniswa zibe izinjini zokushayela futhi zilawule izinjini ngokwenhloso yazo.

Izinjini zikagesi zokushayela ziphinde zihlukaniswe zibe amathuluzi kagesi (okuhlanganisa ukubhola, ukupholishwa, ukupholisha, ukucwilisa, ukusika, nokwandisa amathuluzi), izinjini zikagesi zempahla yasendlini (okuhlanganisa nemishini yokuwasha, iziphephetha-moya zikagesi, iziqandisi, ama-air conditioner, amarekhodi, iziqopha-video, Izidlali ze-DVD, izicoci zomshini, amakhamera, izifutha zikagesi, izishicileli zikagesi, njll.), nezinye izinto ezijwayelekile eziyimishini ezincane (okuhlanganisa amathuluzi emishini emincane ehlukahlukene, imishini emincane, okokwelashwa, amathuluzi kagesi, njll.).

Izinjini zokulawula ziphinde zihlukaniswe ngama-motor stepper nama-servo motors.

⑤ Ukuhlukaniswa ngesakhiwo se-rotor

Ngokwesakhiwo se-rotor, ama-motor kagesi angahlukaniswa abe ama-cage induction motors (ngaphambili ayewaziwa ngokuthi ama-squirrel cage asynchronous motors) kanye nama-rotor induction motors (ngaphambili ayewaziwa ngokuthi ama-motor asynchronous motors).

⑥ Kuhlukaniswa ngesivinini sokusebenza

Amamotho kagesi angahlukaniswa abe amamotho anesivinini esikhulu, amamotho anejubane eliphansi, amamotho esivinini esingaguquki, namamotho esivinini aguquguqukayo ngokuya ngesivinini sawo sokusebenza.

⑦ Ukuhlukaniswa ngefomu lokuvikela

a.Vula uhlobo (njenge-IP11, IP22).

Ngaphandle kwesakhiwo sokusekela esidingekayo, i-motor ayinakho ukuvikelwa okukhethekile kwezingxenye ezijikelezayo neziphilayo.

b.Uhlobo oluvaliwe (njenge-IP44, IP54).

Izingxenye ezijikelezayo neziphilayo ngaphakathi kwe-motor casing zidinga isivikelo esidingekayo ukuze zivimbele ukuthintana ngengozi, kodwa akuvimbeli ngokuphawulekayo ukungena komoya.Amamotho avikelayo ahlukaniswe abe yizinhlobo ezilandelayo ngokuya ngezakhiwo zawo ezihlukene zokungena komoya kanye nokuvikela.

ⓐ Uhlobo lwekhava ye-Mesh.

Izimbobo zokungenisa umoya zenjini zimbozwe ngembobo enezimbobo ukuvimbela izingxenye ezijikelezayo neziphilayo zenjini ukuthi zingathintani nezinto zangaphandle.

ⓑ Ukumelana nokuconsa.

Isakhiwo se-motor vent singavimbela uketshezi oluwa luthi mpo noma okuqinile ekungeneni ngokuqondile ngaphakathi kwenjini.

ⓒ Ubufakazi be-splash.

Isakhiwo se-motor vent singavimbela uketshezi noma okuqinile ukuthi kungangeni ngaphakathi kwenjini kunoma iyiphi indlela ngaphakathi kwe-engeli eqondile engu-100 °.

ⓓ Ivaliwe.

Isakhiwo se-motor casing singavimbela ukushintshaniswa kwamahhala komoya ngaphakathi nangaphandle kwe-casing, kodwa akudingi ukubekwa uphawu okuphelele.

ⓔ Ingangeni manzi.

Isakhiwo se-motor casing singavimbela amanzi ngengcindezi ethile ukuthi angene ngaphakathi kwe-motor.

ⓕ Amanzi.

Lapho i-motor icwiliswa emanzini, ukwakheka kwe-motor casing kungavimbela amanzi ukuthi angangeni ngaphakathi kwe-motor.

ⓖ Isitayela sokuntywila.

Injini kagesi ingasebenza emanzini isikhathi eside ngaphansi kwengcindezi yamanzi elinganiselwe.

ⓗ Ubufakazi bokuqhuma.

Isakhiwo se-motor casing sanele ukuvimbela ukuqhuma kwegesi ngaphakathi kwe-motor ukuthi ingadluliseli ngaphandle kwe-motor, okubangela ukuqhuma kwegesi evuthayo ngaphandle kwe-motor.I-akhawunti esemthethweni ethi “Mechanical Engineering Literature”, igalaji likaphethiloli lonjiniyela!

⑧ Ihlukaniswa ngokungenisa umoya kanye nezindlela zokupholisa

a.Ukuzipholisa ngokwakho.

Amamotho kagesi ancike kuphela emisebeni engaphezulu kanye nokugeleza komoya okungokwemvelo ukuze kuphole.

b.I-self cooled fan.

Injini kagesi ishayelwa isiphephetha-moya esinikeza umoya opholile ukupholisa indawo noma ingaphakathi lemoto.

c.Waphola.

I-fan ehlinzeka ngomoya opholile ayishayelwa injini kagesi ngokwayo, kodwa iqhutshwa ngokuzimela.

d.Uhlobo lwepayipi lokungena komoya.

Umoya opholile awethulwa ngokuqondile noma awukhishwe ngaphandle kwenjini noma ngaphakathi kwenjini, kodwa uyangeniswa noma ukhishwe enjini ngamapayipi.Amafeni okungena komoya wepayipi angakwazi ukuzipholisa ngokwakho noma enye ifeni epholile.

e.Ukupholisa uketshezi.

Izinjini zikagesi zipholiswa ngoketshezi.

f.Ukupholisa igesi yesekethe evaliwe.

Ukujikeleza okuphakathi kokupholisa injini kumjikelezo ovaliwe ohlanganisa injini kanye ne-cooler.Indawo epholile imunca ukushisa lapho idlula kumotho futhi ikhiphe ukushisa lapho idlula endaweni epholile.

g.Ukupholisa ubuso nokupholisa kwangaphakathi.

Indawo yokupholisa engadluli ngaphakathi kwekhondakta yemoto ibizwa ngokuthi i-surface cooling, kanti indawo yokupholisa edlula ngaphakathi kwekhondakta yemoto ibizwa ngokuthi ukupholisa kwangaphakathi.

⑨ Ukuhlelwa ngefomu lesakhiwo sokufaka

Ifomu lokufaka lama-motor kagesi ngokuvamile limelelwa amakhodi.

Ikhodi imelwe isifinyezo se-IM sokufakwa kwamanye amazwe,

Uhlamvu lokuqala ku-IM lumele uhlobo lwekhodi yokufaka, u-B umele ukufakwa okuvundlile, futhi u-V umele ukufakwa okuqondile;

Idijithi yesibili imele ikhodi yesici, emelwe izinombolo zesi-Arabhu.

⑩ Ukwahlukanisa ngokwezinga lokwahlukanisa

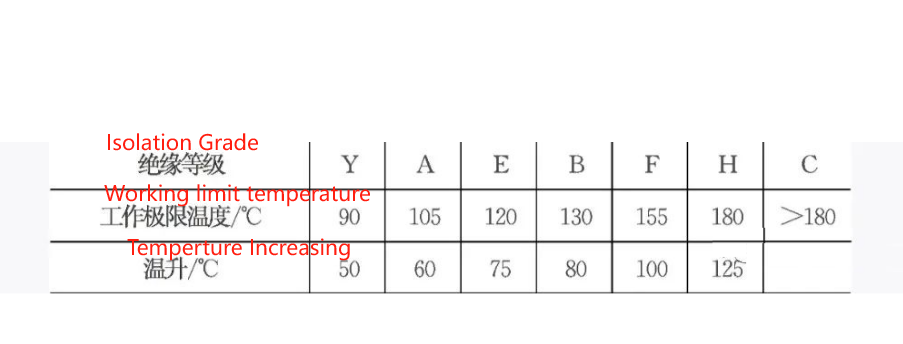

Ileveli A, E-leveli, B-leveli, F-leveli, H-leveli, C-leveli.Ukuhlukaniswa kwezinga le-insulation of motors kukhonjisiwe kuthebula elingezansi.

⑪ Ihlukaniswa ngokwamahora okusebenza alinganiselwe

Isistimu yokusebenza eqhubekayo, ephakathi, neyesikhashana.

Uhlelo Lwemisebenzi Eqhubekayo (SI).Injini iqinisekisa ukusebenza kwesikhathi eside ngaphansi kwenani elilinganiselwe elishiwo ku-nameplate.

Amahora okusebenza esikhathi esifushane (S2).Injini ingasebenza kuphela isikhathi esilinganiselwe ngaphansi kwenani elilinganiselwe elishiwo ku-nameplate.Kunezinhlobo ezine zamazinga obude besikhathi sokusebenza kwesikhashana: 10min, 30min, 60min, kanye 90min.

Uhlelo lokusebenza lwesikhashana (S3).Injini ingasetshenziswa kuphela ngezikhathi ezithile futhi ngezikhathi ezithile ngaphansi kwenani elilinganiselwe elishiwo ku-nameplate, elivezwe njengephesenti lemizuzu eyi-10 ngomjikelezo ngamunye.Isibonelo, i-FC=25%;Phakathi kwazo, i-S4 kuye ku-S10 iyingxenye yezinhlelo zokusebenza ezisebenza ngezikhathi ezithile ngaphansi kwezimo ezihlukene.

9.2.3 Amaphutha ajwayelekile ezinjini zikagesi

Ama-motor kagesi avame ukuhlangana namaphutha ahlukahlukene ngesikhathi sokusebenza isikhathi eside.

Uma ukudluliswa kwe-torque phakathi kwesixhumi nesinciphisi kukhulu, imbobo yokuxhuma endaweni ye-flange ibonisa ukugqoka okunzima, okwandisa igebe elifanele lokuxhuma futhi kuholela ekudlulisweni kwe-torque engazinzile;Ukuguga kwesimo sokuthwala okubangelwa ukulimala kwe-motor shaft bear;Gqoka phakathi kwamakhanda e-shaft kanye nokhiye, njll. Ngemva kokuvela kwezinkinga ezinjalo, izindlela zendabuko ngokuyinhloko zigxila ekulungiseni i-welding noma umshini womshini ngemva kokuxubha ibhulashi, kodwa kokubili kunezithiyo ezithile.

Ukucindezeleka okushisayo okukhiqizwa ukushisa okuphezulu kokulungiswa kwe-welding akukwazi ukuqedwa ngokuphelele, okujwayele ukugoba noma ukuphuka;Kodwa-ke, i-brush plating ilinganiselwe ubukhulu be-coating futhi ijwayele ukuxebuka, futhi zombili izindlela zisebenzisa insimbi ukulungisa insimbi, engakwazi ukushintsha ubuhlobo "obunzima kuya kobunzima".Ngaphansi kwesenzo esihlanganisiwe samandla ahlukahlukene, kusazobangela ukugqoka kabusha.

Amazwe aseNtshonalanga yesimanje avame ukusebenzisa izinto eziyinhlanganisela ye-polymer njengezindlela zokulungisa ukubhekana nalezi zinkinga.Ukusetshenziswa kwezinto ze-polymer zokulungiswa akuthinti ukucindezelwa kwe-welding, futhi ukujiya kokulungisa akunqunyelwe.Ngasikhathi sinye, izinto zensimbi ezisemkhiqizweni azinakho ukuguquguquka kokumunca umthelela nokudlidliza kwemishini, gwema amathuba okuguga kabusha, futhi andise impilo yesevisi yezingxenye zemishini, konga isikhathi esiningi sokuphumula samabhizinisi kanye ukudala inani elikhulu lezomnotho.

(1) Iphutha elenzeka: Injini ayikwazi ukuqala ngemuva kokuxhunywa

Izizathu nezindlela zokusingatha zimi kanje.

① Iphutha lokuvala izintambo ze-Stator - hlola izintambo bese ulungisa iphutha.

② Vula isekethe ku-stator winding, isisekelo sesifunda esifushane, isifunda esivulekile ekusongelweni kwe-rotor motor yesilonda - khomba iphuzu lephutha bese ulisusa.

③ Umthwalo owedlulele noma indlela yokudlulisela ebambekile - hlola indlela yokudlulisa nomthwalo.

④ Vula isifunda kumjikelezo we-rotor we-rotor motor yesilonda (ukuxhumana okungalungile phakathi kwebhulashi kanye nendandatho yesiliphu, isifunda esivulekile ku-rheostat, ukuthintana okungalungile ekuholeni, njll.) - khomba indawo yesifunda evulekile futhi uyilungise.

⑤ Amandla kagesi aphansi kakhulu - hlola imbangela bese uyiqeda.

⑥ Ukulahlekelwa kwesigaba sokuphakelwa kwamandla - hlola isifunda bese ubuyisela isigaba sesithathu.

(2) Iphutha elenzeka: Izinga lokushisa lemoto likhuphuka kakhulu noma liyabhema

Izizathu nezindlela zokusingatha zimi kanje.

① Ukulayishwa ngokweqile noma kuqale kaningi kakhulu - yehlisa umthwalo futhi wehlise inani lokuqalwa.

② Ukulahlekelwa kwesigaba ngesikhathi sokusebenza - hlola isifunda futhi ubuyisele isigaba sesithathu.

③ Iphutha lokuvala izintambo - hlola izintambo bese uzilungisa.

④ I-stator winding isekelwe phansi, futhi kukhona ukujikeleza okufushane phakathi kokujika noma izigaba - khomba indawo ephansi noma yesifunda esifushane bese uyilungisa.

⑤ I-rotor yekheji iphukile - buyisela i-rotor.

⑥ Ukusebenza kwesigaba esingekho sokuphenduka kwe-rotor yesilonda - khomba indawo enephutha futhi ulilungise.

⑦ Ukungqubuzana phakathi kwe-stator ne-rotor - Hlola ama-bearings kanye ne-rotor ngokushintshashintsha, ukulungiswa noma ukushintshwa.

⑧ Ukungena komoya okungalungile - hlola ukuthi umoya awuvimbekile yini.

⑨ I-voltage iphezulu kakhulu noma iphansi kakhulu - Hlola imbangela bese uyiqeda.

(3) Iphutha elenzeka: Ukudlidliza kwemoto okweqile

Izizathu nezindlela zokusingatha zimi kanje.

① I-rotor engalingani - ibhalansi yokulinganisa.

② I-pulley engalingani noma isandiso se-shaft egobile - hlola futhi ulungise.

③ I-motor ayihambisani ne-eksisi yomthwalo - hlola futhi ulungise i-eksisi yeyunithi.

④ Ukufakwa okungafanele kwenjini - hlola ukufakwa nezikulufu zesisekelo.

⑤ Ukugcwala okungazelelwe - nciphisa umthwalo.

(4)Iphutha elenzeka: Umsindo ongajwayelekile ngesikhathi sokusebenza

Izizathu nezindlela zokusingatha zimi kanje.

① Ukungqubuzana phakathi kwe-stator ne-rotor - Hlola ama-bearings kanye ne-rotor ukuze kuguquke, kulungiswe noma kushintshwe.

② Ama-bearings awonakele noma angagcotshisiwe kahle - shintsha futhi uhlanze ama-bearings.

③ Ukusebenza kwesigaba sokulahlekelwa kwezimoto - hlola indawo evulekile yesifunda bese uyilungisa.

④ Ukushayisana kwe-blade ne-casing - hlola futhi ususe amaphutha.

(5) Iphutha elenzeka: Isivinini semoto siphansi kakhulu uma sithwele

Izizathu nezindlela zokusingatha zimi kanje.

① I-voltage yokuphakela amandla iphansi kakhulu - hlola i-voltage yokuhlinzeka amandla.

② Umthwalo oweqile - hlola umthwalo.

③ I-rotor yekheji iphukile - buyisela i-rotor.

④ Ukuthintana okungalungile noma okunqanyuliwe kwesigaba esisodwa seqembu lezintambo ze-rotor ezimazombezombe - hlola ingcindezi yebhulashi, ukuthintana phakathi kwebhulashi nendandatho yokushelela, kanye nokujika kwe-rotor.

(6) Iphutha elenzeka: I-motor casing ibukhoma

Izizathu nezindlela zokusingatha zimi kanje.

① Ukungaqini kahle phansi noma ukumelana nokuqina okuphezulu - Xhuma intambo yaphansi ngokuvumelana nemithethonqubo ukuze uqede amaphutha aphansi aphansi.

② Ama-windings anomswakama - athole ukwelashwa okomiswa.

③ Ukulimala kwe-insulation, ukushayisana komthofu - Gcobisa upende ukuze ulungise ukufakwa, xhuma kabusha imikhondo.9.2.4 Izinqubo zokusebenza kwezimoto

① Ngaphambi kokuqaqa, sebenzisa umoya ocindezelwe ukuze ukhiphe uthuli olungaphezulu kwemoto futhi uyisule ihlanzeke.

② Khetha indawo yokusebenza ye-motor disassembly bese uhlanza indawo esendaweni.

③ Ujwayelene nezici zesakhiwo kanye nezidingo zobuchwepheshe zokulondolozwa kwamamotho kagesi.

④ Lungiselela amathuluzi adingekayo (okuhlanganisa amathuluzi akhethekile) nezinto zokusebenza zokuqaqa.

⑤ Ukuze kuqondwe kabanzi amaphutha ekusebenzeni kwenjini, ukuhlolwa kokuhlolwa kungenziwa ngaphambi kokuhlakazwa uma izimo zivuma.Kulokhu, injini ihlolwe ngomthwalo, futhi izinga lokushisa, umsindo, ukudlidliza, nezinye izimo zengxenye ngayinye yemoto zihlolwe ngokuningiliziwe.I-voltage, yamanje, isivinini, njll. nazo ziyahlolwa.Khona-ke, umthwalo unqanyuliwe futhi ukuhlolwa okuhlukile kokuhlolwa kokungalayishi kwenziwa ukuze kulinganiswe ukulahlekelwa kwamanje nokungabikho komthwalo, futhi amarekhodi enziwa.I-akhawunti esemthethweni ethi “Mechanical Engineering Literature”, igalaji likaphethiloli lonjiniyela!

⑥ Nqamula ugesi, susa izintambo zangaphandle zenjini, futhi ugcine amarekhodi.

⑦ Khetha i-voltage megohmmeter efanelekile ukuze uhlole ukumelana nokufakwa kwenjini.Ukuze uqhathanise amanani okumelana nokufakwa kukalwa ngesikhathi sokulungiswa kokugcina ukuze kunqunywe inkambiso yokushintsha kokufakwa kwe-insulation kanye nesimo se-insulation senjini, amanani okumelana nokufakwa kwe-insulation akalwa kumazinga okushisa ahlukene kufanele aguqulelwe ezingeni lokushisa elifanayo, ngokuvamile aguqulelwe ku-75 ℃.

⑧ Hlola isilinganiso sokumuncwa K. Uma isilinganiso sokumuncwa K>1.33, sibonisa ukuthi ukugqunywa kwenjini akuthintwa umswakama noma izinga lomswakama alibi kakhulu.Ukuze uqhathanise nedatha yangaphambilini, kuyadingeka futhi ukuguqula isilinganiso sokumuncwa esikalwa kunoma yiliphi izinga lokushisa kuya kumazinga okushisa afanayo.

9.2.5 Ukugcinwa nokulungiswa kwezinjini zikagesi

Lapho injini isebenza noma ingasebenzi kahle, kunezindlela ezine zokuvimbela nokuqeda amaphutha ngesikhathi, okungukuthi, ukubuka, ukulalela, ukuhogela, nokuthinta, ukuqinisekisa ukusebenza okuphephile kwemoto.

(1) Bheka

Qaphela uma kukhona okungavamile ngesikhathi sokusebenza kwemoto, okubonakaliswa ikakhulukazi ezimweni ezilandelayo.

① Uma ukuma kwe-stator kukufushane, intuthu ingase ibonakale enjini.

② Uma i-motor igcwele kakhulu noma iphelelwa isigaba, ijubane lizohamba kancane futhi kuzoba nomsindo "ozwakalayo" osindayo.

③ Lapho injini igijima ngokujwayelekile, kodwa ima kungazelelwe, izinhlansi zingase zivele ekuxhumekeni okuxekethile;Isenzakalo sokushaywa kwe-fuse noma ingxenye yokubambeka.

④ Uma injini idlidliza ngamandla, kungase kube ngenxa yokuminyana kwedivayisi yokudlulisela, ukungalungisi kahle kwenjini, amabhawudi esisekelo axegayo, njll.

⑤ Uma kukhona ukuguquguquka kombala, izimpawu zokusha, namabala entuthu ezindaweni ezixhumene nangaphakathi kanye nezixhumi zenjini, kubonisa ukuthi kungase kube khona ukushisa okweqile kwendawo, ukuthintana okungekuhle ekuxhumekeni kwamakhondatha, noma amawindi ashile.

(2) Lalela

Injini kufanele ikhiphe umsindo ofanayo kanye nolula "wokukhalayo" ngesikhathi sokusebenza okuvamile, ngaphandle kwanoma yimuphi umsindo noma imisindo ekhethekile.Uma kukhishwa umsindo omkhulu kakhulu, okuhlanganisa umsindo kazibuthe, umsindo ozwakalayo, umsindo wokungenisa umoya, umsindo wokungqubuzana komshini, njll., kungase kube isandulela noma into yokungasebenzi kahle.

① Ngomsindo we-electromagnetic, uma injini ikhipha umsindo omkhulu futhi osindayo, kungase kube nezizathu ezimbalwa.

a.Igebe lomoya phakathi kwe-stator ne-rotor alilingani, futhi umsindo ushintshashintsha ukusuka phezulu ukuya phansi ngesikhathi esifanayo sokuphumula phakathi kwemisindo ephezulu nephansi.Lokhu kubangelwa ukugqoka okuthwala, okubangela ukuthi i-stator ne-rotor ingagxili.

b.Umsinga wezigaba ezintathu awulingani.Lokhu kungenxa yesisekelo esingalungile, isifunda esifushane, noma ukuthintana okungalungile kwezigaba ezintathu zokujika.Uma umsindo ulula kakhulu, kubonisa ukuthi injini igcwele kakhulu noma iphelelwa yisigaba.

c.I-iron core evulekile.Ukudlidliza kwenjini ngesikhathi sokusebenza kubangela ukuba amabhawodi okulungisa emongo wensimbi axege, okubangela ukuba ishidi lensimbi ye-silicon lixege futhi likhiphe umsindo.

② Ukuze uthole umsindo, kufanele uqashelwe njalo phakathi nokusebenza kwemoto.Indlela yokuqapha iwukucindezela umkhawulo owodwa we-screwdriver endaweni ekhuphukayo yokuthwala, kanti enye iseduze nendlebe ukuze uzwe umsindo we-bearing egijima.Uma i-bearing isebenza ngendlela evamile, umsindo wayo uyoba umsindo “oheshazayo” oqhubekayo nomncane, ngaphandle kokuguquguquka kobude noma umsindo wokungqubuzana kwensimbi.Uma le misindo elandelayo ivela, kuthathwa njengokungavamile.

a.Kukhona umsindo "ohlabayo" lapho i-bearing isebenza, okuwumsindo we-metal friction, ngokuvamile obangelwa ukuntuleka kwamafutha ekuthwaleni.I-bearing kufanele ihlakazwe futhi yengezwe ngenani elifanele lamafutha okugcoba.

b.Uma kunomsindo othi "creaking", umsindo owenziwa lapho ibhola lizungeza, ngokuvamile okubangelwa ukomiswa kwamafutha okugcoba noma ukuntuleka kwamafutha.Inani elifanele lamafutha lingengezwa.

c.Uma kunomsindo othi "chofoza" noma "we-creaking", umsindo okhiqizwa ukunyakaza okungavamile kwebhola ekuthwaleni, okubangelwa ukulimala kwebhola ekuthwaleni noma ukusetshenziswa kwesikhathi eside kwe-motor. , kanye nokomiswa kwamafutha okugcoba.

③ Uma indlela yokudlulisela kanye nendlela eqhutshwayo ikhipha imisindo eqhubekayo kunemisindo eguquguqukayo, ingaphathwa ngezindlela ezilandelayo.

a.Imisindo "ephumayo" ngezikhathi ezithile ibangelwa amalunga amabhande angalingani.

b.Umsindo othi "thumping" ngezikhathi ezithile ubangelwa ukuhlangana okuxekethile noma i-pulley phakathi kwama-shafts, kanye nokhiye abagugile noma okhiye.

c.Umsindo wokushayisana ongalingani ubangelwa ama-wind blades ashayisana nekhava yabalandeli.

(3) Iphunga

Ngokuhogela iphunga lenjini, amaphutha angabonwa futhi avinjwe.Uma kutholakala iphunga elikhethekile lopende, libonisa ukuthi izinga lokushisa langaphakathi lemoto liphezulu kakhulu;Uma kutholakala iphunga elinamandla elishisiwe noma elishisiwe, kungase kube ngenxa yokuwohloka kwesendlalelo se-insulation noma ukushiswa kwe-winding.

(4) Thinta

Ukuthinta izinga lokushisa kwezinye izingxenye zemoto nakho kunganquma imbangela yokungasebenzi kahle.Ukuqinisekisa ukuphepha, ingemuva lesandla kufanele lisetshenziswe ukuthinta izingxenye ezizungezile ze-motor casing kanye nama-bearings lapho uthinta.Uma kutholakala okungavamile kwezinga lokushisa, kungase kube nezizathu ezimbalwa.

① Ukungena komoya okungalungile.Okufana nokuhlangana kwabalandeli, imigudu evalekile yokungenisa umoya, njll.

② Ukugcwala.Ukubangela amandla amanje ngokweqile kanye nokushisa ngokweqile kwe-stator winding.

③ Umjikelezo omfushane phakathi kwama-stator windings noma ukungalingani kwamanje kwezigaba ezintathu.

④ Ukuqala noma ukubhuleka njalo.

⑤ Uma izinga lokushisa elizungeze i- bearing liphezulu kakhulu, kungase kubangelwe ukuthwala umonakalo noma ukuntuleka kukawoyela.

Isikhathi sokuthumela: Oct-06-2023