1. Isingeniso Sezimoto Zikagesi

Injini kagesi iyithuluzi eliguqula amandla kagesi abe amandla omshini. Lisebenzisa ikhoyili enamandla (okungukuthi i-stator winding) ukukhiqiza insimu yamagnetic ejikelezayo bese lisebenza ku-rotor (njengekheji le-squirrel elivaliwe ngohlaka lwe-aluminium) ukwakha i-magnetoelectric rotational torque.

Ama-motor kagesi ahlukaniswe ngama-motor e-DC kanye nama-motor e-AC ngokwemithombo yamandla ehlukene esetshenziswayo. Iningi lama-motor ohlelweni lwamandla ama-motor e-AC, angaba ama-motor ahambisanayo noma ama-motor angenawo ukuvumelanisa (isivinini se-stator magnetic field se-motor asigcini isivinini esihambisanayo nesivinini sokujikeleza kwe-rotor).

Injini kagesi ikakhulukazi yakhiwe yi-stator kanye ne-rotor, futhi isiqondiso samandla asebenza entanjeni enikwe amandla ensimini yamagnetic sihlobene nesiqondiso samandla kagesi kanye nesiqondiso somugqa wokungenisa amandla kagesi (isiqondiso sensimu yamagnetic). Isimiso sokusebenza senjini kagesi umphumela wensimu yamagnetic emandleni asebenza kumandla kagesi, okubangela ukuba imoto ijikeleze.

2. Ukwahlukaniswa kwama-motor kagesi

① Ukuhlukaniswa ngogesi osebenzayo

Ngokusho kwemithombo yamandla ahlukene asebenzayo yama-motor kagesi, angahlukaniswa ngama-motor e-DC kanye nama-motor e-AC. Ama-motor e-AC ahlukaniswe futhi ngama-motor esigaba esisodwa kanye nama-motor esigaba sesithathu.

② Ukuhlukaniswa ngesakhiwo kanye nomgomo wokusebenza

Ama-motor kagesi angahlukaniswa ngama-DC motors, ama-motor asynchronous, kanye nama-motor asynchronous ngokuya ngesakhiwo sawo kanye nomgomo wawo wokusebenza. Ama-motor asynchronous angahlukaniswa futhi abe ama-motor asynchronous ahlala njalo, ama-motor asynchronous asynchronous, kanye nama-motor asynchronous asynchronous. Ama-motor asynchronous angahlukaniswa abe ama-motor angenisayo kanye nama-motor a-AC commutator. Ama-motor angenisayo ahlukaniswe futhi abe ama-motor asynchronous anezigaba ezintathu kanye nama-motor asynchronous ane-shaded pole. Ama-motor a-AC commutator ahlukaniswe futhi abe ama-motor avuselelekayo anezigaba ezintathu, ama-motor a-AC DC asebenzisa izindlela ezimbili, kanye nama-motor axoshayo.

③ Kuhlukaniswe ngokwendlela yokuqalisa kanye nemodi yokusebenza

Ama-motor kagesi angahlukaniswa ngama-motor angenasi-synchronous aqalwe yi-capacitor single-phase, ama-motor angenasi-synchronous aqalwe yi-capacitor single-phase, ama-motor angenasi-synchronous aqalwe yi-capacitor single-phase, kanye nama-motor angenasi-synchronous aqalwe yi-phase single-phase ngokwezindlela zawo zokuqala nezokusebenza.

④ Ukuhlukaniswa ngokwenhloso

Ama-motor kagesi angahlukaniswa abe ama-driver motors kanye nama-control motors ngokwenhloso yawo.

Ama-motor kagesi okushayela ahlukaniswe kabanzi ngamathuluzi kagesi (kufaka phakathi ukubhoboza, ukupholisha, ukupholisha, ukufaka izikhala, ukusika, kanye namathuluzi okwandisa), ama-motor kagesi ezinto zasendlini (kufaka phakathi imishini yokuwasha, amafeni kagesi, amafriji, ama-air conditioner, ama-recorder, ama-video recorder, ama-DVD player, ama-vacuum cleaner, amakhamera, ama-electric blowers, ama-electric shaver, njll.), kanye neminye imishini emincane ejwayelekile yemishini (kufaka phakathi amathuluzi emishini amancane ahlukahlukene, imishini emincane, imishini yezokwelapha, amathuluzi kagesi, njll.).

Ama-control motors ahlukaniswe kabanzi ngama-stepper motors kanye nama-servo motors.

⑤ Ukuhlukaniswa ngesakhiwo se-rotor

Ngokwesakhiwo se-rotor, ama-motor kagesi angahlukaniswa ngama-motor okungenisa izikeji (ngaphambili ayaziwa ngokuthi ama-squirrel cage asynchronous motors) kanye nama-motor okungenisa izikeji ama-wound rotor (ngaphambilini ayaziwa ngokuthi ama-motor asynchronous motors).

⑥ Kuhlukaniswe ngesivinini sokusebenza

Ama-motor kagesi angahlukaniswa ngama-motor anejubane eliphezulu, ama-motor anejubane eliphansi, ama-motor anejubane elingaguquki, kanye nama-motor anejubane eliguquguqukayo ngokwejubane lawo lokusebenza.

⑦ Ukuhlukaniswa ngokwesimo sokuvikela

a. Uhlobo oluvulekile (njenge-IP11, i-IP22).

Ngaphandle kwesakhiwo sokusekela esidingekayo, injini ayinaso isivikelo esikhethekile sezingxenye ezijikelezayo neziphilayo.

b. Uhlobo oluvaliwe (njenge-IP44, i-IP54).

Izingxenye ezijikelezayo neziphilayo ngaphakathi kwebhokisi lemoto zidinga ukuvikelwa okudingekile komshini ukuvimbela ukuthintana ngengozi, kodwa akuvimbeli kakhulu ukuphefumula. Ama-motor avikelayo ahlukaniswe ngezinhlobo ezilandelayo ngokuya ngezakhiwo zawo zokuphefumula nezivikelayo ezahlukene.

ⓐ Uhlobo lwesembozo se-mesh.

Izimbobo zokungenisa umoya zemoto zimbozwe ngezimbobo ezinezimbobo ukuvimbela izingxenye ezijikelezayo neziphilayo zemoto ukuthi zingathintani nezinto zangaphandle.

ⓑ Ayinawo amaconsi.

Isakhiwo somoya womoya wemoto singavimbela uketshezi noma izinto eziqinile eziwela ziqonde phezulu ukuthi zingangeni ngqo ngaphakathi kwemoto.

ⓒ Ukuvikela ukuqhekeka.

Isakhiwo somoya womoya wemoto singavimbela uketshezi noma izinto eziqinile ukuthi zingangeni ngaphakathi kwemoto nganoma iyiphi indlela ngaphakathi kwebanga eliqondile elingu-100 °.

ⓓ Kuvaliwe.

Isakhiwo sebhokisi lenjini singavimbela ukushintshaniswa komoya ngaphakathi nangaphandle kwebhokisi, kodwa akudingi ukuvalwa okuphelele.

ⓔ Okungangeni manzi.

Isakhiwo sebhokisi lenjini singavimbela amanzi ngengcindezi ethile ukuthi angene ngaphakathi kwenjini.

ⓕ Ayinamanzi.

Uma injini icwiliswa emanzini, isakhiwo sebhokisi lenjini singavimbela amanzi ukuthi angene ngaphakathi kwenjini.

ⓖ Isitayela sokuntywila.

Injini kagesi ingasebenza emanzini isikhathi eside ngaphansi kwengcindezi yamanzi elinganisiwe.

ⓗ Ubufakazi bokuqhuma.

Isakhiwo sebhokisi lemoto sanele ukuvimbela ukuqhuma kwegesi ngaphakathi kwemoto ukuthi kungadluliselwa ngaphandle kwemoto, okubangela ukuqhuma kwegesi evuthayo ngaphandle kwemoto. I-akhawunti esemthethweni ethi “Mechanical Engineering Literature”, isiteshi sikaphethiloli sonjiniyela!

⑧ Kuhlukaniswa ngezindlela zokungenisa umoya kanye nokupholisa

a. Ukuzipholisa.

Ama-motor kagesi athembele kuphela emisebeni engaphezulu kanye nokugeleza komoya wemvelo ukuze aphole.

b. Ifeni elizipholisa ngokwalo.

Injini kagesi iqhutshwa ngumuntu ophehla umoya opholile ukuze apholise ubuso noma ingaphakathi lenjini.

c. Ifeni yakhe ipholile.

Ifeni enikeza umoya opholile ayiqhutshwa yimoto kagesi uqobo, kodwa iqhutshwa ngokuzimela.

d. Uhlobo lokungenisa umoya emapayipini.

Umoya opholile awungeniswa ngokuqondile noma awukhishwa ngaphandle kwemoto noma ngaphakathi kwemoto, kodwa ungeniswa noma ukhishwa kusuka emotweni ngamapayipi. Amafeni okungenisa umoya emapayipini angapholiswa yimoto ngokwayo noma apholiswe yimoto.

e. Ukupholisa uketshezi.

Ama-motor kagesi apholiswa ngoketshezi.

f. Ukupholisa igesi yesekethe evaliwe.

Ukujikeleza okuphakathi kokupholisa imoto kusendaweni evaliwe ehlanganisa imoto kanye ne-cooler. Indawo epholile imunca ukushisa lapho idlula emotweni futhi ikhipha ukushisa lapho idlula e-cooler.

g. Ukupholisa okungaphezulu kanye nokupholisa kwangaphakathi.

Indawo yokupholisa engadluli ngaphakathi komqhubi wemoto ibizwa ngokuthi ukupholisa okungaphezulu, kanti indawo yokupholisa edlula ngaphakathi komqhubi wemoto ibizwa ngokuthi ukupholisa kwangaphakathi.

⑨ Ukuhlukaniswa ngefomu lesakhiwo sokufakwa

Uhlobo lokufakwa kwama-motor kagesi luvame ukumelwa ngamakhodi.

Ikhodi imelelwa yisifinyezo se-IM sokufakwa kwamanye amazwe,

Uhlamvu lokuqala ku-IM lumelela ikhodi yohlobo lokufaka, u-B umele ukufakwa okuvundlile, kanti u-V umele ukufakwa okuvundlile;

Inombolo yesibili imele ikhodi yesici, emelelwa izinombolo zesi-Arabhu.

⑩ Ukuhlukaniswa ngokwezinga lokufakwa kokushisa

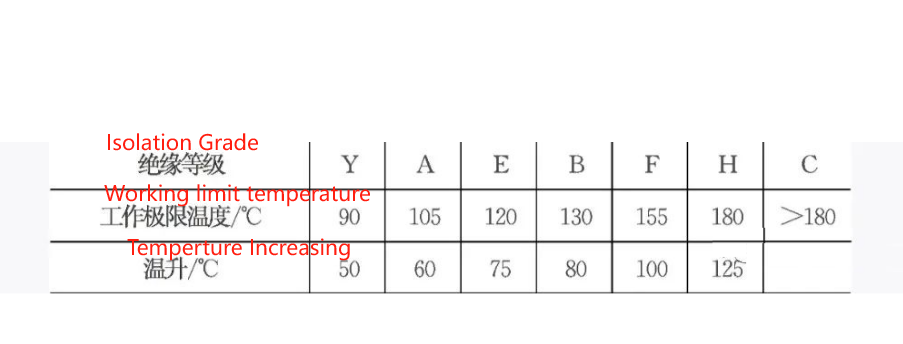

Izinga le-A, izinga le-E, izinga le-B, izinga le-F, izinga le-H, izinga le-C. Ukuhlukaniswa kwezinga lokufakwa kwama-motor kuboniswa kuthebula elingezansi.

⑪ Kuhlukaniswe ngokwezikhathi zokusebenza ezilinganiselwe

Uhlelo lokusebenza oluqhubekayo, oluhlala lukhona, nolwesikhashana.

Uhlelo Lomsebenzi Oqhubekayo (SI). Injini iqinisekisa ukusebenza kwesikhathi eside ngaphansi kwenani elilinganiselwe elichazwe ku-nameplate.

Amahora okusebenza esikhathi esifushane (S2). Injini ingasebenza isikhathi esilinganiselwe kuphela ngaphansi kwenani elilinganiselwe elichazwe ku-nameplate. Kunezinhlobo ezine zezindinganiso zesikhathi sokusebenza kwesikhashana: imizuzu eyi-10, imizuzu engama-30, imizuzu engama-60, kanye nemizuzu engama-90.

Uhlelo lokusebenza oluqhubekayo (S3). Injini ingasetshenziswa kuphela ngezikhathi ezithile nangokwezikhathi ezithile ngaphansi kwenani elilinganiselwe elichazwe ku-nameplate, elivezwa njengephesenti lemizuzu eyi-10 ngomjikelezo ngamunye. Isibonelo, i-FC=25%; Phakathi kwazo, i-S4 kuya ku-S10 ingezinye zezinhlelo zokusebenza zokusebenza ngezikhathi ezithile eziningana ngaphansi kwezimo ezahlukene.

9.2.3 Amaphutha avamile ezinjini zikagesi

Ama-motor kagesi avame ukubhekana namaphutha ahlukahlukene ngesikhathi sokusebenza isikhathi eside.

Uma ukudluliswa kwe-torque phakathi kwesixhumi kanye ne-reducer kukhulu, imbobo yokuxhuma ebusweni be-flange ikhombisa ukuguguleka okukhulu, okwandisa igebe lokulingana kokuxhumeka futhi kuholele ekudlulisweni kwe-torque okungazinzile; Ukuguguleka kwesikhundla sokuthwala okubangelwa ukulimala kwebheyaringi ye-motor shaft; Ukuguguleka phakathi kwamakhanda e-shaft kanye ne-keyways, njll. Ngemva kokuvela kwezinkinga ezinjalo, izindlela zendabuko zigxila kakhulu ekulungiseni ukushisela noma ekushiseni ngemuva kokufaka ibhulashi, kodwa zombili zinezinkinga ezithile.

Ukucindezeleka kokushisa okubangelwa ukushisela kokulungisa izinga lokushisa eliphezulu akukwazi ukususwa ngokuphelele, okuvame ukugoba noma ukuphuka; Kodwa-ke, i-brush plating inqunyelwe ubukhulu be-coating futhi ivame ukuxebuka, futhi zombili izindlela zisebenzisa insimbi ukulungisa insimbi, engenakukwazi ukushintsha ubudlelwano "obuqinile kuya kobunzima". Ngaphansi kwesenzo esihlangene samandla ahlukahlukene, isazoqhubeka nokuguga.

Amazwe aseNtshonalanga yanamuhla avame ukusebenzisa izinto ezihlanganisiwe ze-polymer njengezindlela zokulungisa ukubhekana nalezi zinkinga. Ukusetshenziswa kwezinto ze-polymer zokulungisa akuthinti ukucindezeleka kokushisa kokushisela, futhi ubukhulu bokulungisa abunqunyelwe. Ngesikhathi esifanayo, izinto zensimbi ezikumkhiqizo azinawo amandla okumunca umthelela nokudlidliza kwemishini, zigweme amathuba okuguga kabusha, futhi zandise impilo yesevisi yezingxenye zemishini, zisindise isikhathi esiningi sokungasebenzi kwamabhizinisi futhi zidale inani elikhulu lezomnotho.

(1) Isenzakalo sephutha: Injini ayikwazi ukuqala ngemva kokuxhunywa

Izizathu kanye nezindlela zokusingatha yilezi ezilandelayo.

① Iphutha lentambo yokugoqa i-stator – hlola intambo bese ulungisa iphutha.

② Isekethe evulekile ekugoqeni kwe-stator, ukumisa isekethe esifushane, isekethe evulekile ekugoqeni kwenjini ye-rotor yesilonda - thola indawo yephutha bese uyisusa.

③ Umthwalo omningi noma indlela yokudlulisa ebambekile – hlola indlela yokudlulisa kanye nomthwalo.

④ Vula isekethe kusekethe ye-rotor yenjini ye-rotor enesilonda (ukuxhumana okungekuhle phakathi kwebhulashi nendandatho yokushelela, isekethe evulekile ku-rheostat, ukuxhumana okungekuhle ku-lead, njll.) - thola iphuzu lesekethe evulekile bese ulilungisa.

⑤ I-voltage yokunikezwa kwamandla iphansi kakhulu - hlola imbangela bese uyisusa.

⑥ Ukulahleka kwesigaba sokunikezwa kwamandla – hlola isekethe bese ubuyisela izigaba ezintathu.

(2) Isenzakalo sephutha: Ukushisa kwemoto kukhuphuka kakhulu noma kubhema

Izizathu kanye nezindlela zokusingatha yilezi ezilandelayo.

① Kugcwele kakhulu noma kuqalwe kaningi kakhulu – nciphisa umthwalo bese unciphisa inani lokuqalisa.

② Ukulahlekelwa yisigaba ngesikhathi sokusebenza – hlola isekethe bese ubuyisela izigaba ezintathu.

③ Iphutha lentambo yokugoqa i-stator – hlola intambo bese uyilungisa.

④ Ukugoqa kwe-stator kusekelwe phansi, futhi kukhona isekethe elifushane phakathi kokujika noma izigaba - thola indawo yesekethe elifushane noma phansi bese uyilungisa.

⑤ I-rotor yekheji ephihliwe - shintsha i-rotor.

⑥ Ukusebenza kwesigaba esingekho sokugoqa kwe-rotor yenxeba - thola indawo yephutha bese uyilungisa.

⑦ Ukungqubuzana phakathi kwe-stator ne-rotor – Hlola amabheringi ne-rotor ukuze kutholakale ukuthi aguqukile, ayalungiswa noma ayashintshwa.

⑧ Ukungena komoya okungekuhle – hlola ukuthi ukungena komoya akuphazamisekile yini.

⑨ I-voltage iphezulu kakhulu noma iphansi kakhulu – Hlola imbangela bese uyisusa.

(3) Isenzakalo sephutha: Ukudlidliza okukhulu kwenjini

Izizathu kanye nezindlela zokusingatha yilezi ezilandelayo.

① I-rotor engalingani – ibhalansi yokulinganisa.

② Isandiso se-pulley noma somshafti esingalingani – hlola bese ulungisa.

③ Injini ayihambisani ne-axis yomthwalo - hlola bese ulungisa i-axis yeyunithi.

④ Ukufakwa okungafanele kwenjini - hlola ukufakwa kanye nezikulufo zesisekelo.

⑤ Ukulayisha ngokweqile okungazelelwe – nciphisa umthwalo.

(4) Isenzakalo sephutha: Umsindo ongajwayelekile ngesikhathi sokusebenza

Izizathu kanye nezindlela zokusingatha yilezi ezilandelayo.

① Ukungqubuzana phakathi kwe-stator ne-rotor – Hlola amabheringi ne-rotor ukuthi aguqukile, ayalungiswa noma ayashintshwa.

② Ama-bearing onakele noma angagcotshwanga kahle – shintsha futhi uhlanze ama-bearing.

③ Ukusebenza kokulahlekelwa yisigaba senjini – hlola indawo yesekethe evulekile bese uyilungisa.

④ Ukushayisana kwe-blade ne-casing - hlola futhi ususe amaphutha.

(5) Isenzakalo sephutha: Ijubane lemoto liphansi kakhulu uma lingaphansi komthwalo

Izizathu kanye nezindlela zokusingatha yilezi ezilandelayo.

① I-voltage yokunikezwa kwamandla iphansi kakhulu - hlola i-voltage yokunikezwa kwamandla.

② Umthwalo omningi – hlola umthwalo.

③ I-rotor yekheji ephihliwe - shintsha i-rotor.

④ Ukuxhumana okubi noma okungaxhunywanga kwesigaba esisodwa seqembu lezintambo ze-rotor ezigoqayo - hlola ingcindezi yebhulashi, ukuxhumana phakathi kwebhulashi nendandatho yokushelela, kanye nokugoqa kwe-rotor.

(6) Isenzakalo sephutha: Ibhokisi lenjini liyasebenza

Izizathu kanye nezindlela zokusingatha yilezi ezilandelayo.

① Ukumelana nokufakwa komhlabathi okubi noma ukumelana nokufakwa komhlabathi okuphezulu – Xhuma ucingo lomhlabathi ngokwemithetho ukuze uqede amaphutha okufakwa komhlabathi okubi.

② Amawindi aswakeme - aphathwa ngokomiswa.

③ Umonakalo wokufakwa kokushisa, ukushayisana komthofu - Upende wokucwilisa ukuze kulungiswe ukufakwa kokushisa, xhuma kabusha umthofu. 9.2.4 Izinqubo zokusebenza kwenjini

① Ngaphambi kokuyiqaqa, sebenzisa umoya ocindezelwe ukuze uphephule uthuli ebusweni bemoto bese uyisula kahle.

② Khetha indawo yokusebenzela yokuqaqa imoto bese uhlanza indawo ezungezile.

③ Ngijwayelene nezici zesakhiwo kanye nezidingo zobuchwepheshe zokugcinwa kwama-motor kagesi.

④ Lungisa amathuluzi adingekayo (kufaka phakathi amathuluzi akhethekile) kanye nemishini yokuwaqaqa.

⑤ Ukuze kuqondwe kabanzi amaphutha ekusebenzeni kwemoto, ukuhlolwa kokuhlolwa kungenziwa ngaphambi kokuyihlukanisa uma izimo zivuma. Ngenxa yalokhu, imoto ihlolwa ngomthwalo, bese izinga lokushisa, umsindo, ukudlidliza, nezinye izimo zengxenye ngayinye yemoto zihlolwa ngokuningiliziwe. I-voltage, i-current, isivinini, njll. nazo ziyahlolwa. Ngemuva kwalokho, umthwalo uyanqanyulwa bese kwenziwa ukuhlolwa okuhlukile kokuhlolwa okungenamthwalo ukuze kulinganiswe ukulahleka kwamanje okungenamthwalo kanye nokulahlekelwa okungenamthwalo, bese kwenziwa amarekhodi. I-akhawunti esemthethweni ethi “Mechanical Engineering Literature”, isiteshi sikaphethiloli sonjiniyela!

⑥ Nquma ugesi, susa izintambo zangaphandle zemoto, bese ugcina amarekhodi.

⑦ Khetha i-megohmmeter ye-voltage efanelekile ukuhlola ukumelana nokushisa kwemoto. Ukuze kuqhathaniswe amanani okumelana nokushisa okulinganiswe ngesikhathi sokulungiswa kokugcina ukuze kutholakale ukuthambekela kokushintsha kokushisa kanye nesimo sokushisa kwemoto, amanani okumelana nokushisa okulinganiswe emazingeni okushisa ahlukene kufanele aguqulwe abe amazinga okushisa afanayo, ngokuvamile aguqulwe abe ngu-75 ℃.

⑧ Hlola isilinganiso sokumunca K. Uma isilinganiso sokumunca K>1.33, sibonisa ukuthi ukufudumala kwemoto akuthintekile umswakama noma izinga lomswakama alilibi kakhulu. Ukuze kuqhathaniswe nedatha yangaphambilini, kuyadingeka futhi ukuguqula isilinganiso sokumunca esilinganiswe kunoma yiliphi izinga lokushisa sibe yizinga lokushisa elifanayo.

9.2.5 Ukugcinwa nokulungiswa kwama-motor kagesi

Uma injini isebenza noma ingasebenzi kahle, kunezindlela ezine zokuvimbela nokususa amaphutha ngesikhathi esifanele, okungukuthi, ukubuka, ukulalela, ukuhogela, kanye nokuthinta, ukuqinisekisa ukusebenza okuphephile kwenjini.

(1) Ukubukeka

Qaphela ukuthi kukhona yini ukuphazamiseka ngesikhathi sokusebenza kwemoto, okubonakala kakhulu ezimweni ezilandelayo.

① Uma ukugoqa kwe-stator kufinyelelwe kumjikelezo omfushane, intuthu ingabonakala enjinini.

② Uma injini igcwele kakhulu noma iphelelwa yisigaba, ijubane lizoncipha futhi kuzoba nomsindo "ovuthayo" osindayo.

③ Uma injini isebenza ngendlela evamile, kodwa ngokuzumayo ima, kungase kuvele izinhlansi lapho kuxhunywa khona; Isimo sokushaywa kwefusi noma ingxenye ethile inamathela.

④ Uma injini idlidliza ngamandla, kungenzeka ukuthi kungenxa yokuvaleka kwedivayisi yokudlulisa, ukungabambeki kahle kwenjini, amabhawodi esisekelo axegayo, njll.

⑤ Uma kukhona ukushintsha kombala, izimpawu zokusha, kanye namabala entuthu ezindaweni zokuxhumana zangaphakathi kanye nokuxhumana kwemoto, lokhu kubonisa ukuthi kungase kube nokushisa okwedlulele endaweni, ukuxhumana okubi ezindaweni zokuxhumanisa, noma ama-windings ashile.

(2) Lalela

Injini kufanele ikhiphe umsindo ofanayo nolula “oqhumayo” ngesikhathi sokusebenza okuvamile, ngaphandle komsindo noma imisindo ekhethekile. Uma kukhishwa umsindo omningi kakhulu, okuhlanganisa umsindo we-electromagnetic, umsindo wamabhere, umsindo wokungenisa umoya, umsindo wokungqubuzana komshini, njll., kungaba yisandulela noma isenzakalo sokungasebenzi kahle.

① Uma kwenzeka umsindo we-electromagnetic, uma injini ikhipha umsindo omkhulu nosindayo, kungase kube nezizathu eziningana.

a. Igebe lomoya phakathi kwe-stator ne-rotor alilingani, futhi umsindo uyashintshashintsha kusukela phezulu kuya phansi ngesikhathi esifanayo sokuphumula phakathi kwemisindo ephezulu nephansi. Lokhu kubangelwa ukuguguleka kwamabhere, okwenza i-stator ne-rotor zingagxili.

b. Ugesi wezigaba ezintathu awulingani. Lokhu kungenxa yokuma okungalungile, i-short circuit, noma ukuthintana okungekuhle kwe-three-phase winding. Uma umsindo ubuthakathaka kakhulu, kubonisa ukuthi injini igcwele kakhulu noma iphelelwa yisigaba.

c. Ingaphakathi lensimbi elixegayo. Ukudlidliza kwenjini ngesikhathi sokusebenza kubangela ukuthi amabhawodi okuqinisa ingaphakathi lensimbi axegayo, okwenza ishidi lensimbi le-silicon lengaphakathi lensimbi likhululeke futhi likhiphe umsindo.

② Ngomsindo we-bearing, kufanele uqashwe njalo ngesikhathi sokusebenza kwenjini. Indlela yokuqapha iwukucindezela uhlangothi olulodwa lwesikulufi endaweni yokufaka ye-bearing, kanti olunye uhlangothi luseduze nendlebe ukuze uzwe umsindo we-bearing ugijima. Uma i-bearing isebenza kahle, umsindo wayo uzoba umsindo oqhubekayo noncane "oqhumayo", ngaphandle kokushintshashintsha kokuphakama noma umsindo wokungqubuzana kwensimbi. Uma kuvela imisindo elandelayo, kubhekwa njengokungajwayelekile.

a. Kunomsindo "wokukhala" lapho i-bearing isebenza, okuwumsindo wokungqubuzana kwensimbi, ovame ukubangelwa ukuntuleka kwamafutha ku-bearing. I-bearing kufanele ihlukaniswe futhi ifakwe inani elifanele lamafutha okugcoba.

b. Uma kukhona umsindo "wokuklewula", umsindo owenziwa lapho ibhola lijikeleza, ngokuvamile obangelwa ukoma kwamafutha okugcoba noma ukuntuleka kwamafutha. Kungangezwa inani elifanele lamafutha.

c. Uma kukhona umsindo “wokuchofoza” noma “wokuklewula”, umsindo odalwa ukunyakaza okungajwayelekile kwebhola kubhereyi, okubangelwa umonakalo webhola kubhereyi noma ukusetshenziswa kwesikhathi eside kwenjini, kanye nokomiswa kwamafutha okugcoba.

③ Uma indlela yokudlulisa kanye nendlela eqhutshwayo kukhipha imisindo eqhubekayo kunokuba ishintshe, ingaphathwa ngezindlela ezilandelayo.

a. Imisindo “yokuduma” eyenzeka ngezikhathi ezithile ibangelwa yizihlanganisi zebhande ezingalingani.

b. Umsindo "wokuthuthumela" ophindaphindwayo ubangelwa ukuxhuma okuxekethile noma i-pulley phakathi kwama-shaft, kanye nezihluthulelo ezigugile noma izindlela zokhiye.

c. Umsindo wokungqubuzana ongalingani ubangelwa ama-wind blades ashayisana nesembozo sefeni.

(3) Iphunga

Ngokuhogela iphunga lemoto, amaphutha angabonakala futhi avinjelwe. Uma kutholakala iphunga elikhethekile lopende, libonisa ukuthi izinga lokushisa langaphakathi lemoto liphezulu kakhulu; Uma kutholakala iphunga elinamandla lokusha noma lokusha, kungase kube ngenxa yokuwohloka kwesendlalelo sokushisa noma ukusha kwe-winding.

(4) Ukuthinta

Ukuthinta izinga lokushisa kwezinye izingxenye zemoto nakho kunganquma imbangela yokungasebenzi kahle. Ukuqinisekisa ukuphepha, ingemuva lesandla kufanele lisetshenziswe ukuthinta izingxenye ezizungezile zebhokisi lemoto nama-bearings uma uthinta. Uma kutholakala ukungajwayelekile kwezinga lokushisa, kungaba nezizathu eziningana.

① Umoya ongemuhle. Njengokuhlukaniswa kwamafeni, imigudu yomoya evalekile, njll.

② Ukulayisha ngokweqile. Kubangela ugesi omningi kanye nokushisa ngokweqile kwe-stator winding.

③ Ukujikeleza okufushane phakathi kwama-stator windings noma ukungalingani kwamanje kwezigaba ezintathu.

④ Ukuqala noma ukubhuleka njalo.

⑤ Uma izinga lokushisa elizungeze ibhereyi liphezulu kakhulu, kungabangelwa umonakalo webhereyi noma ukuntuleka kwamafutha.

Isikhathi sokuthunyelwe: Okthoba-06-2023