Izici ezithinta ukusetshenziswa kwensimbi okuyisisekelo

Ukuze sihlaziye inkinga, sidinga kuqala ukwazi imibono eyisisekelo, ezosisiza siqonde. Okokuqala, sidinga ukwazi imiqondo emibili. Eyokuqala ukushintshana kwemagnetization, okuyinto, uma siyibeka kalula, eyenzeka enkabeni yensimbi ye-transformer kanye namazinyo e-stator noma e-rotor enjini; Eyokuqala i-rotal magnetization properties, ekhiqizwa yi-stator noma i-rotor joke yenjini. Kunezinhlobo eziningi zezinto eziqala kusukela emaphuzwini amabili bese zibala ukulahlekelwa kwensimbi kwenjini ngokusekelwe ezicini ezahlukene ngokwendlela yesisombululo engenhla. Ukuhlolwa kukhombisile ukuthi amashidi ensimbi e-silicon abonisa lezi zimo ezilandelayo ngaphansi kwe-magnetization yezakhiwo ezimbili:

Uma i-magnetic flux density ingaphansi kwe-1.7 Tesla, ukulahleka kwe-hysteresis okubangelwa i-rotary magnetization kukhulu kunalokho okubangelwa i-alternating magnetization; Uma iphakeme kune-1.7 Tesla, okuphambene nalokho kuyiqiniso. I-magnetic flux density ye-motor jock ngokuvamile iphakathi kwe-1.0 ne-1.5 Tesla, kanti ukulahleka kwe-rotary magnetization hysteresis okufana nakho kukhulu cishe ngo-45 kuya ku-65% kunokulahleka kwe-alternating magnetization hysteresis.

Vele, iziphetho ezingenhla nazo ziyasetshenziswa, futhi angikaze ngiziqinisekise mathupha ekusebenzeni. Ngaphezu kwalokho, lapho insimu yamagnetic enkabeni yensimbi ishintsha, kudalwa ugesi kuwo, obizwa ngokuthi ugesi we-eddy, kanti ukulahlekelwa okubangelwa yiwo kubizwa ngokuthi ugesi we-eddy. Ukuze kuncishiswe ugesi we-eddy, ugesi wensimbi wemoto ngokuvamile awukwazi ukwenziwa ube yibhulokhi eliphelele, futhi ufakwa nge-axial ngamashidi ensimbi avikelwe ukuze kuvinjelwe ukugeleza kogesi we-eddy. Ifomula ethile yokubala yokusetshenziswa kwensimbi ngeke ibe nzima lapha. Ifomula eyisisekelo kanye nokubaluleka kokubalwa kokusetshenziswa kwensimbi ye-Baidu kuzocaca kakhulu. Okulandelayo ukuhlaziywa kwezinto eziningana ezibalulekile ezithinta ukusetshenziswa kwethu kwensimbi, ukuze wonke umuntu akwazi futhi ukuqhubekela phambili noma emuva athole inkinga ezicelweni zobunjiniyela ezisebenzayo.

Ngemva kokuxoxa ngalokhu okungenhla, kungani ukukhiqizwa kokunyathela kuthinta ukusetshenziswa kwensimbi? Izici zenqubo yokubhoboza zincike kakhulu ezimweni ezahlukene zemishini yokubhoboza, futhi zinquma imodi yokushefa ehambisanayo kanye nezinga lokucindezeleka ngokwezidingo zezinhlobo ezahlukene zemigodi nemifantu, ngaleyo ndlela kuqinisekiswe izimo zezindawo zokucindezeleka ezingajulile ezizungeze umngcele we-lamination. Ngenxa yobudlelwano phakathi kokujula nokuma, kuvame ukuthintwa ama-engeli abukhali, kuze kube yilapho amazinga aphezulu okucindezeleka angabangela ukulahlekelwa okukhulu kwensimbi ezindaweni zokucindezeleka ezingajulile, ikakhulukazi emaphethelweni amade okugunda ngaphakathi kobubanzi be-lamination. Ngokukhethekile, kwenzeka kakhulu esifundeni se-alveolar, okuvame ukuba yindawo yokucwaninga enqubweni yocwaningo lwangempela. Amashidi ensimbi e-silicon alahlekelwa kancane avame ukunqunywa ngobukhulu obukhulu bokusanhlamvu. Umthelela ungabangela ama-burrs okwenziwa kanye ne-shear yokuklebhula emaphethelweni angezansi eshidi, futhi i-engeli yomthelela ingaba nomthelela omkhulu kusayizi wama-burrs nezindawo zokuguquguquka. Uma indawo yokucindezeleka ephezulu inwebeka endaweni yokuguquguquka komphetho iye ngaphakathi kwezinto, isakhiwo sokusanhlamvu kulezi zindawo sizobhekana nezinguquko ezifanayo ngokungenakugwenywa, sijijeke noma siqhekeke, futhi ukunwebeka okukhulu komngcele kuzokwenzeka ngendlela yokuklebhula. Ngalesi sikhathi, ubuningi bomngcele wokusanhlamvu endaweni yokucindezeleka ohlangothini lokugunda kuzokhula ngokungenakugwenywa, okuholela ekwandeni okuhambisanayo kokulahlekelwa yinsimbi ngaphakathi kwesifunda. Ngakho-ke, kuleli qophelo, izinto ezisendaweni yokucindezeleka zingabhekwa njengento elahlekelwa kakhulu ewela phezu kwe-lamination evamile eceleni komphetho womthelela. Ngale ndlela, ukuqina kwangempela kwezinto ezisemaphethelweni kunganqunywa, futhi ukulahlekelwa kwangempela komphetho womthelela kunganqunywa ngokwengeziwe kusetshenziswa imodeli yokulahlekelwa yinsimbi.

1. Ithonya Lenqubo Yokunamathela Ekulahlekelweni Kwensimbi

Izimo zethonya lokulahlekelwa yinsimbi zikhona ikakhulukazi esicini samashidi ensimbi e-silicon, futhi ukucindezeleka komshini nokushisa kuzothinta amashidi ensimbi e-silicon ngezinguquko ezicini zawo zangempela. Ukucindezeleka okwengeziwe komshini kuzoholela ekushintsheni kokulahlekelwa yinsimbi. Ngesikhathi esifanayo, ukwanda okuqhubekayo kokushisa kwangaphakathi kwemoto kuzophinde kukhuthaze ukuvela kwezinkinga zokulahlekelwa yinsimbi. Ukuthatha izinyathelo ezisebenzayo zokunciphisa ukucindezeleka okwengeziwe komshini kuzoba nomthelela omuhle ekunciphiseni ukulahleka kwensimbi ngaphakathi kwemoto.

2. Izizathu zokulahlekelwa ngokweqile ezinqubweni zokukhiqiza

Amashidi ensimbi ye-silicon, njengezinto eziyinhloko ezisebenza ngamandla kazibuthe zama-motor, anomthelela omkhulu ekusebenzeni kwe-motor ngenxa yokuhambisana kwawo nezidingo zomklamo. Ngaphezu kwalokho, ukusebenza kwamashidi ensimbi ye-silicon esezingeni elifanayo kungahluka kubakhiqizi abahlukene. Lapho kukhethwa izinto, kufanele kwenziwe imizamo yokukhetha izinto ezivela kubakhiqizi bensimbi ye-silicon abahle. Ngezansi kunezinye izici ezibalulekile ezithinte ukusetshenziswa kwensimbi okuye kwahlangatshezwana nazo ngaphambili.

Ishidi lensimbi ye-silicon alizange lifakwe uthango noma liphathwe kahle. Lolu hlobo lwenkinga lungatholakala ngesikhathi senqubo yokuhlola amashidi ensimbi ye-silicon, kodwa akubona bonke abakhiqizi bezimoto abanale nto yokuhlola, futhi le nkinga ivame ukungabonwa kahle abakhiqizi bezimoto.

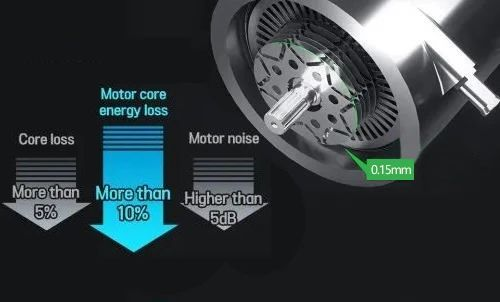

Ukufakwa komoya okonakele phakathi kwamashidi noma amasekethe amafushane phakathi kwamashidi. Lolu hlobo lwenkinga lwenzeka ngesikhathi senqubo yokukhiqiza i-iron core. Uma ingcindezi ngesikhathi sokufakwa komoya okonakele phakathi kwamashidi iphezulu kakhulu, okubangela umonakalo ekufakweni komoya okonakele phakathi kwamashidi; Noma uma ama-burrs emakhulu kakhulu ngemva kokufakwa komoya okonakele, angasuswa ngokupholisha, okuholela ekulimaleni okukhulu ekufakweni komoya okonakele ebusweni bokufakwa komoya okonakele; Ngemva kokuthi ukufakwa komoya okonakele phakathi kwamashidi kuqediwe, umsele awubushelelezi, bese kusetshenziswa indlela yokufaka; Ngaphandle kwalokho, ngenxa yezici ezifana ne-stator bore engalingani kanye nokungahlangani phakathi kwe-stator bore kanye ne-lip yesihlalo somshini, ukujika kungasetshenziswa ukulungisa. Ukusetshenziswa okuvamile kwalezi zinqubo zokukhiqiza nokucubungula izimoto empeleni kunomthelela omkhulu ekusebenzeni kwemoto, ikakhulukazi ukulahlekelwa yinsimbi.

Uma usebenzisa izindlela ezifana nokushisa noma ukufudumeza ngogesi ukuze uhlukanise ukugoqa, kungabangela ukuthi i-iron core ishise ngokweqile, okuholela ekunciphiseni kokuqhuba kwamagnetic kanye nomonakalo ekushiseni phakathi kwamashidi. Le nkinga ivame ukwenzeka ngesikhathi sokulungiswa kokugoqa kanye nenjini ngesikhathi senqubo yokukhiqiza nokucubungula.

Ukushisela nge-stacking nezinye izinqubo nakho kungabangela umonakalo ekushiseni okuphakathi kwezitaki, okwandisa ukulahlekelwa komswakama we-eddy.

Isisindo sensimbi esinganele kanye nokuxinana okungaphelele phakathi kwamashidi. Umphumela wokugcina ukuthi isisindo senhliziyo yensimbi asanele, futhi umphumela oqondile kakhulu ukuthi ugesi udlula ukubekezelelana, kuyilapho kungase kube neqiniso lokuthi ukulahleka kwensimbi kudlula indinganiso.

Isembozo esisephepheni lensimbi ye-silicon sijiyile kakhulu, okwenza isekethe yamagnetic igcwale kakhulu. Ngalesi sikhathi, ijika lobudlelwano phakathi kwamandla kagesi angenamthwalo kanye ne-voltage ligobile kakhulu. Lokhu futhi kuyisici esibalulekile enqubweni yokukhiqiza nokucubungula amashidi ensimbi ye-silicon.

Ngesikhathi sokukhiqizwa nokucutshungulwa kwama-core ensimbi, ukuqondiswa kokusanhlamvu kokubhoboza kanye nokunamathiselwa kobuso bensimbi ye-silicon kungase kulimazeke, okuholela ekwandeni kokulahlekelwa yinsimbi ngaphansi kokufakwa okufanayo kwe-magnetic; Kuma-motor aphindaphindayo, ukulahlekelwa okwengeziwe kwensimbi okubangelwa ama-harmonics kufanele futhi kucatshangelwe; Lesi yisici okufanele sicatshangelwe ngokuphelele enkambisweni yokuklama.

Ngaphezu kwalezi zici ezingenhla, inani lokuklama lokulahlekelwa yinsimbi yemoto kufanele lisekelwe ekukhiqizweni nasekucutshungulweni kwangempela kwe-iron core, futhi kufanele kwenziwe yonke imizamo ukuqinisekisa ukuthi inani lethiyori lihambisana nenani langempela. Ama-curve ajwayelekile anikezwa abahlinzeki bezinto ezijwayelekile alinganiswa kusetshenziswa indlela ye-Epstein square coil, kodwa isiqondiso se-magnetization sezingxenye ezahlukene kumoto sihlukile, futhi lokhu kulahlekelwa yinsimbi ejikelezayo okukhethekile akunakucatshangelwa okwamanje. Lokhu kungaholela emazingeni ahlukahlukene okungahambisani phakathi kwamanani abaliwe namanani alinganisiwe.

Izindlela zokunciphisa ukulahleka kwensimbi ekwakhiweni kobunjiniyela

Kunezindlela eziningi zokunciphisa ukusetshenziswa kwensimbi kwezobunjiniyela, futhi into ebaluleke kakhulu ukwenza umuthi uvumelane nesimo. Yiqiniso, akugcini nje ngokusetshenziswa kwensimbi, kodwa futhi nangokulahlekelwa okunye. Indlela eyisisekelo kunazo zonke ukwazi izizathu zokulahlekelwa kwensimbi ephezulu, njengokuxinana okuphezulu kwamagnetic, imvamisa ephezulu, noma ukugcwala kwendawo ngokweqile. Yiqiniso, ngendlela evamile, ngakolunye uhlangothi, kuyadingeka ukusondela eqinisweni eduze ngangokunokwenzeka ohlangothini lokulingisa, kanti ngakolunye uhlangothi, inqubo ihlanganiswa nobuchwepheshe ukunciphisa ukusetshenziswa kwensimbi okwengeziwe. Indlela evame ukusetshenziswa kakhulu ukwandisa ukusetshenziswa kwamashidi ensimbi e-silicon amahle, futhi kungakhathaliseki ukuthi kubiza malini, insimbi e-super silicon engenisiwe ingakhethwa. Yiqiniso, ukuthuthukiswa kobuchwepheshe obusha obuqhutshwa amandla asekhaya nakho kuholele ekuthuthukisweni okungcono ezindaweni eziphezulu naphansi. Izimboni zensimbi zasekhaya nazo ziqala imikhiqizo ekhethekile yensimbi ye-silicon. I-Genealogy inezinhlobo ezinhle zemikhiqizo zezimo ezahlukene zohlelo lokusebenza. Nazi izindlela ezimbalwa eziqondile ongazibhekana nazo:

1. Lungiselela isekethe yamagnetic

Ukuthuthukisa isekethe yamagnetic, uma sikhuluma iqiniso, ukwenza ngcono i-sine yensimu yamagnetic. Lokhu kubalulekile, hhayi kuphela kumamotha okungenisa imvamisa eqondile. Amamotha okungenisa imvamisa eguquguqukayo kanye namamotha ahambisanayo abalulekile. Ngesikhathi ngisebenza embonini yemishini yezindwangu, ngenza amamotha amabili anokusebenza okuhlukile ukunciphisa izindleko. Yiqiniso, into ebaluleke kakhulu kwakuwukuba khona noma ukungabikho kwezigxobo ezigobile, okwaholela ezicini ze-sinusoidal ezingaguquki zensimu yamagnetic yesikhala somoya. Ngenxa yokusebenza ngesivinini esikhulu, ukulahlekelwa yinsimbi kubalwa ingxenye enkulu, okwaholela emehluko omkhulu ekulahlekelweni phakathi kwamamotha amabili. Ekugcineni, ngemva kokubala okungemuva, umehluko wokulahlekelwa yinsimbi wemoto ngaphansi kwe-algorithm yokulawula ukhuphuke ngaphezu kokuphindwe kabili. Lokhu kukhumbuza wonke umuntu ukuthi ahlanganise ama-algorithm okulawula lapho enza amamotha okulawula isivinini semvamisa eguquguqukayo futhi.

2.Nciphisa ukuminyana kwamagnetic

Ukwandisa ubude bomgogodla wensimbi noma ukwandisa indawo yokuqhuba amandla kazibuthe yesekethe kazibuthe ukuze kuncishiswe ukuminyana kwamandla kazibuthe, kodwa inani lensimbi esetshenziswa kumoto liyakhula ngokufanele;

3. Ukunciphisa ukujiya kwama-chip ensimbi ukuze kuncishiswe ukulahleka kwamandla kagesi abangelwayo

Ukufaka amashidi ensimbi ye-silicon aguqisiwe ashisayo esikhundleni samashidi ensimbi ye-silicon aguqisiwe abandayo kunganciphisa ukujiya kwamashidi ensimbi ye-silicon, kodwa amashidi ensimbi amancane azokwandisa inani lamashidi ensimbi kanye nezindleko zokukhiqiza izimoto;

4. Ukwamukela amashidi ensimbi e-silicon aqoqwe ngokubandayo anomoya omuhle wamagnetic ukuze kuncishiswe ukulahleka kwe-hysteresis;

5. Ukwamukela ukugqoka kwe-iron chip okusebenzayo okuphezulu;

6. Ukwelashwa kokushisa kanye nobuchwepheshe bokukhiqiza

Ukucindezeleka okusele ngemva kokucubungula ama-iron chips kungathinta kakhulu ukulahlekelwa kwenjini. Lapho kucubungula amashidi ensimbi e-silicon, indlela yokusika kanye nokucindezeleka kokucheba okubhoboza kunomthelela omkhulu ekulahlekelweni kwe-iron core. Ukusika ngendlela yokugoqa yeshidi lensimbi le-silicon nokwenza ukwelashwa kokushisa eshidini lensimbi le-silicon kunganciphisa ukulahlekelwa ngo-10% kuya ku-20%.

Isikhathi sokuthunyelwe: Novemba-01-2023