Iinjiniumgodi awunalutho, usebenza kahle ekushabalaliseni ukushisa futhi ungakhuthaza ukukhanya okululainjini.Ngaphambilini, imiphini yezimoto yayiqinile kakhulu, kodwa ngenxa yokusetshenziswa kwemiphini yezimoto, ukucindezeleka kwakuvame ukugxila ebusweni bomphini, kanti ukucindezeleka enkabeni kwakuncane kakhulu. Ngokwezakhiwo zokugoba kanye nokugoba kwezinto zokwakha, ingxenye yangaphakathi yeinjiniumgodi wawugobile ngendlela efanele, futhi kwakudingeka ububanzi obuncane bangaphandle kuphela ukuze kwandiswe ingxenye yangaphandle. Umgodi ogobile ungahlangabezana nokusebenza okufanayo nomgodi oqinile, kodwa isisindo sawo singancishiswa kakhulu. Okwamanje, ngenxa yomgodi ogobileinjiniUmshafti, uwoyela wokupholisa ungangena ngaphakathi komshafti wemoto, wandise indawo yokushaja ukushisa futhi uthuthukise ukusebenza kahle kokushaja ukushisa. Ngaphansi komkhuba wamanje wokushaja okusheshayo kwe-800V high-voltage, inzuzo yemishafti yemoto engenalutho inkulu. Izindlela zamanje zokukhiqiza imishafti yemoto engenalutho zifaka phakathi ukugoba komgodi oqinile, ukushisela, kanye nokwakheka okuhlanganisiwe, phakathi kwazo ukushisela kanye nokwakheka okuhlanganisiwe kusetshenziswa kabanzi ekukhiqizeni.

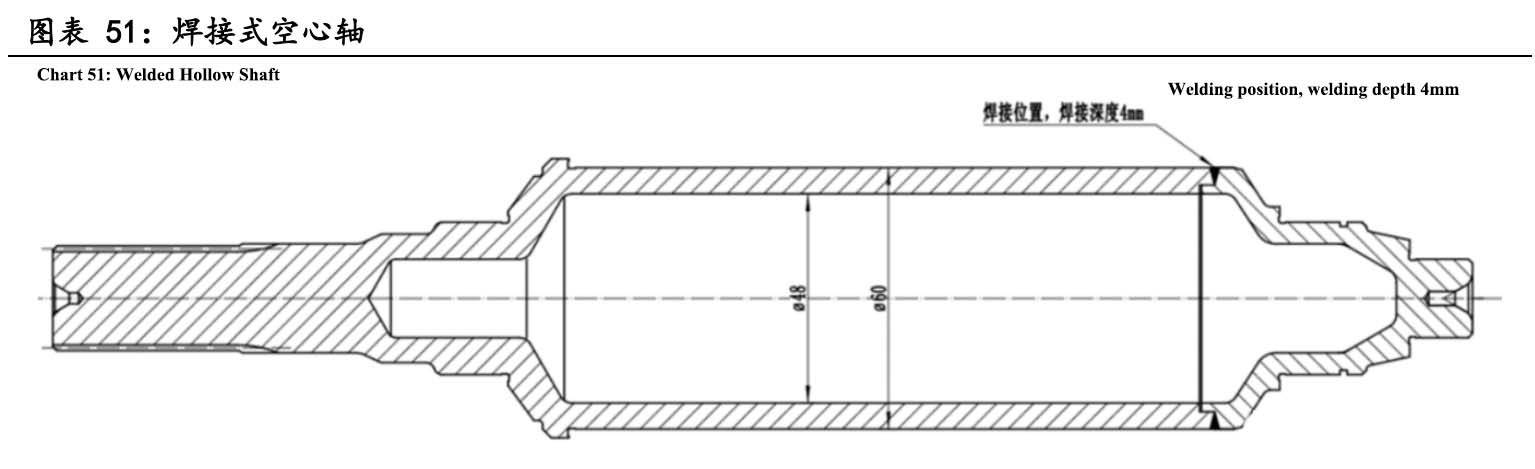

Umgodi ongenalutho ohlanganisiwe utholakala kakhulu ngokwakhiwa kwe-extrusion ukuze kufezwe imbobo yangaphakathi enezinyathelo zomgodi, bese ushintshwa ngomshini bese ushintshwa ube yisimo. Ngokubumba i-extrusion, izinguquko zesimo sembobo yangaphakathi ngesakhiwo somkhiqizo nezidingo zamandla zigcinwa ngangokunokwenzeka. Ngokuvamile, ubukhulu bodonga oluyisisekelo lomkhiqizo bungaklanywa ngaphansi kuka-5mm. Imishini yokushisela ngokuvamile isebenzisa ukushisela kwe-butt friction noma i-laser welding. Uma kusetshenziswa ukushisela kwe-butt friction, indawo ye-butt joint ngokuvamile icishe ibe yi-3mm welding protrusion. Ukusebenzisa ukushisela kwe-laser, ukujula kokushisela ngokuvamile kuphakathi kuka-3.5 no-4.5mm, futhi amandla okushisela angaqinisekiswa ukuthi angaphezu kuka-80% we-substrate. Abanye abahlinzeki bangafinyelela ngisho nangaphezu kuka-90% wamandla e-substrate ngezinyathelo zokulawula inqubo eqinile. Ngemva kokuthi ukushisela kwe-hollow shaft sekuqediwe, kuyadingeka ukwenza ukuhlolwa kwe-ultrasonic noma kwe-X-ray kusakhiwo esincane kanye nekhwalithi yokushisela yendawo yokushisela ukuqinisekisa ukuhambisana komkhiqizo.

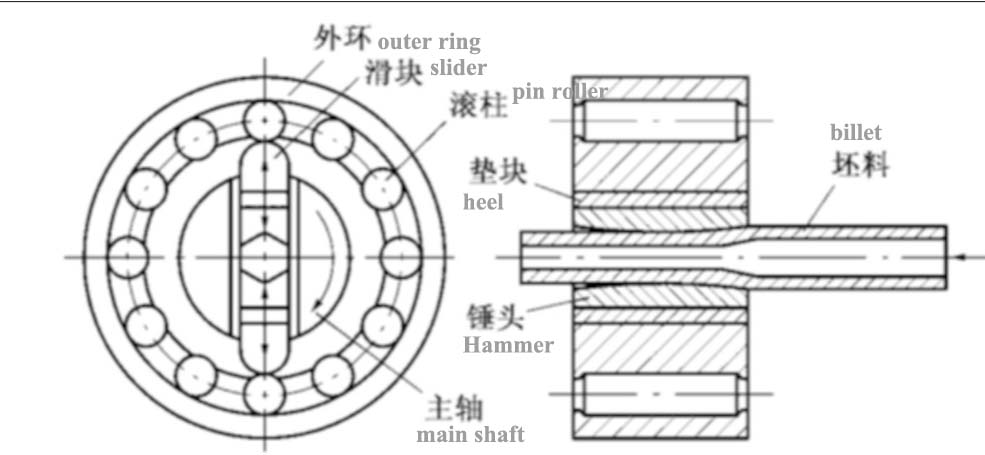

Umgodi ongenalutho ohlanganisiwe uhlanganiswa kakhulu yimishini yangaphandle endaweni engenalutho, okwenza ingxenye yangaphakathi ikwazi ukufeza ngqo imbobo yangaphakathi enezinyathelo zomgodi. Njengamanje, i-radial forging kanye ne-rotary forging zisetshenziswa kakhulu, futhi imishini ingeniswa kakhulu. I-radial forging ijwayelekile yemishini yenkampani i-FELLS, kuyilapho i-rotary forging ijwayelekile yemishini yenkampani ye-GFM. I-radial forging forming ivame ukufezwa ngokusebenzisa izando ezine noma ngaphezulu ezilinganayo ngemvamisa yokushaya okungaphezu kuka-240 ngomzuzu ukuze kufezwe ukuguqulwa okuncane kwe-blank kanye ne-hollow tube blank forming eqondile. I-rotary forging forming inqubo yokuhlela ngokulinganayo amakhanda amaningi e-hammer ohlangothini oluzungezile lwe-billet. Ikhanda le-hammer lijikeleza i-axis ngenkathi lenza i-radial high-frequency forging endaweni yokusebenza, kunciphisa usayizi we-cross-sectional we-billet futhi kwande nge-axial ukuze kutholakale indawo yokusebenza. Uma kuqhathaniswa ne-solid shafts yendabuko, izindleko zokukhiqiza ze-hollow shafts ezihlanganisiwe zizokhuphuka cishe ngo-20%, kodwa isisindo se-motor shafts ngokuvamile sizoncishiswa ngo-30-35%.

Isikhathi sokuthunyelwe: Septhemba 15-2023