Uma kuqhathaniswa nama-radial flux motors, ama-axial flux motors anezinzuzo eziningi ekwakhiweni kwezimoto zikagesi. Isibonelo, ama-axial flux motors angashintsha ukwakheka kwe-powertrain ngokuhambisa imoto kusuka ku-axle iye ngaphakathi kwamasondo.

1. I-axis yamandla

Ama-motor e-Axial fluxzithola ukunakwa okwandayo (ukuthola amandla okudonsa). Sekuyiminyaka eminingi lolu hlobo lwenjini lusetshenziswa ezindleleni ezimile njengezikhulisi kanye nemishini yezolimo, kodwa eminyakeni eyishumi edlule, abathuthukisi abaningi bebesebenza ukuthuthukisa lobu buchwepheshe futhi babusebenzise ezithuthuthu zikagesi, ezikhungweni zezindiza, emalolini ezimpahla, ezimotweni zikagesi, ngisho nasezindizeni.

Ama-radial flux motors endabuko asebenzisa oma-magnets abangapheli noma ama-induction motors, athuthuke kakhulu ekwenzeni ngcono isisindo nezindleko. Kodwa-ke, abhekene nobunzima obuningi ekuqhubekeni nokukhula. I-Axial flux, uhlobo oluhluke ngokuphelele lwemoto, ingaba yindlela enhle.

Uma kuqhathaniswa nama-radial motors, indawo esebenza kahle yamagnetic yama-axial flux permanent magnet motors iwubuso be-motor rotor, hhayi ububanzi bangaphandle. Ngakho-ke, kumthamo othile wemoto, ama-axial flux permanent magnet motors ngokuvamile anganikeza i-torque enkulu.

Ama-motor e-Axial fluxzincane kakhulu; Uma kuqhathaniswa nama-radial motors, ubude be-axial bemoto bufushane kakhulu. Kuma-wheel motors angaphakathi, lokhu kuvame ukuba yisici esibalulekile. Isakhiwo esiqinile sama-axial motors siqinisekisa ubuningi bamandla aphezulu kanye nobuningi be-torque kunema-radial motors afanayo, ngaleyo ndlela kuqedwe isidingo sejubane lokusebenza eliphezulu kakhulu.

Ukusebenza kahle kwama-axial flux motors nakho kuphakeme kakhulu, ngokuvamile kudlula u-96%. Lokhu kungenxa yendlela ye-flux emfushane, enobukhulu obubodwa, elingana noma ephakeme kakhulu ngokusebenza kahle uma kuqhathaniswa nama-radial flux motors amahle kakhulu e-2D emakethe.

Ubude benjini bufushane, ngokuvamile bufushane ngokuphindwe ka-5 kuya ku-8, kanti isisindo sincishiswa ngokuphindwe ka-2 kuya ku-5. Lezi zici ezimbili zishintshe ukukhetha kwabaklami beplatifomu yezimoto zikagesi.

2. Ubuchwepheshe be-Axial flux

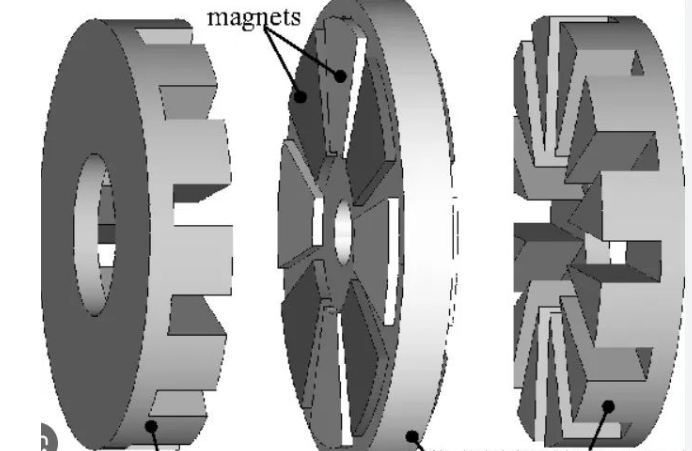

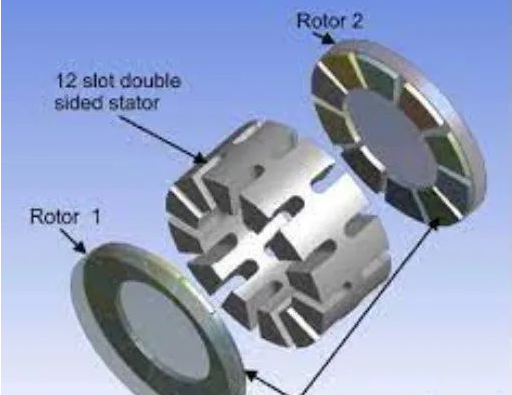

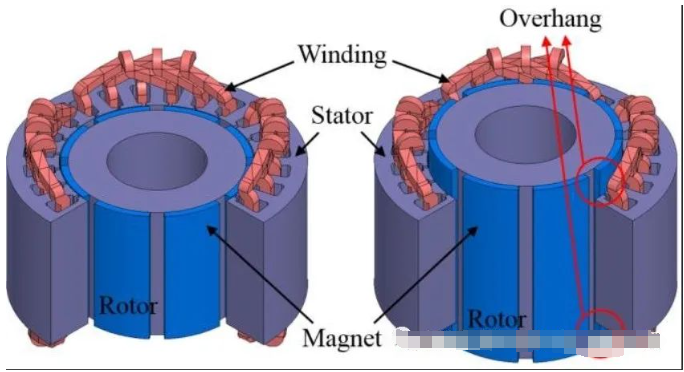

Kunezinhlobo ezimbili eziyinhloko ze-topologyama-motor e-axial flux: i-rotor ephindwe kabili i-single stator (ngezinye izikhathi ibizwa ngokuthi imishini yesitayela se-torus) kanye ne-rotor ephindwe kabili i-rotor.

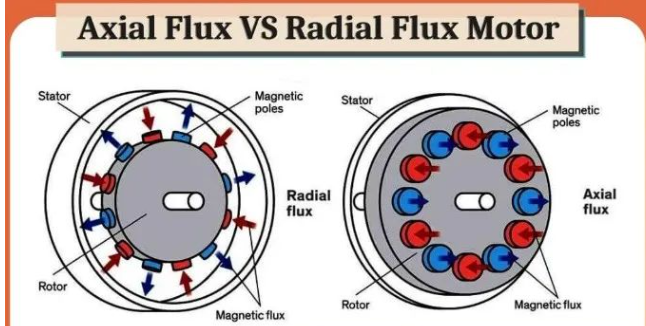

Njengamanje, iningi lama-magnet motor ahlala njalo asebenzisa i-radial flux topology. Isekethe ye-magnetic flux iqala nge-unomphela ku-rotor, idlule ngezinyo lokuqala ku-stator, bese igeleza nge-radially ku-stator. Bese idlula ngezinyo lesibili ukuze ifinyelele insimbi yesibili yamagnetic ku-rotor. Ku-dual rotor axial flux topology, i-flux loop iqala kusuka ku-magnet yokuqala, idlule nge-axial ngokusebenzisa amazinyo e-stator, bese ifika ngokushesha ku-magnet yesibili.

Lokhu kusho ukuthi indlela yokushintshashintsha imfushane kakhulu kuneyezimoto ze-radial flux, okuholela ekukhuleni kwezimoto ezincane, ubuningi bamandla aphezulu kanye nokusebenza kahle ngamandla afanayo.

Injini ye-radial, lapho i-magnetic flux idlula khona ezinyweni zokuqala bese ibuyela ezinyweni ezilandelayo nge-stator, ifinyelele kumagnet. I-magnetic flux ilandela indlela enezinhlangothi ezimbili.

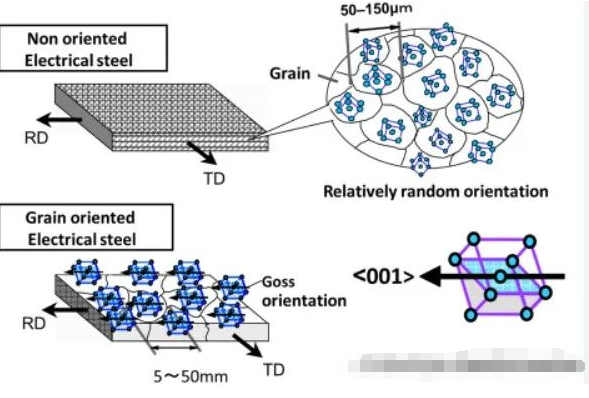

Indlela yokugeleza kwamagnetic yomshini we-axial magnetic flux inobukhulu obubodwa, ngakho-ke insimbi kagesi eqondiswe kokusanhlamvu ingasetshenziswa. Le nsimbi yenza kube lula ukuthi i-flux idlule, ngaleyo ndlela kuthuthukiswe ukusebenza kahle.

Ama-motor e-radial flux ngokuvamile asebenzisa ama-winding asakazekile, kanti kuze kube yingxenye yeziphetho zokugoba azisebenzi. I-coil overhang izoholela esisindweni esengeziwe, izindleko, ukumelana nogesi, kanye nokulahlekelwa ukushisa okwengeziwe, okuphoqa abaklami ukuthi bathuthukise umklamo wokugoba.

Iziphetho zekhoyiliama-motor e-axial fluxzincane kakhulu, futhi eminye imiklamo isebenzisa ama-winding agxilile noma ahlukaniswe, asebenza kahle ngokuphelele. Emishinini ye-stator radial ehlukaniswe, ukuqhekeka kwendlela ye-magnetic flux ku-stator kungaletha ukulahlekelwa okwengeziwe, kodwa kuma-axial flux motors, lokhu akuyona inkinga. Ukwakheka kwe-coil winding kuyisihluthulelo sokuhlukanisa izinga labaphakeli.

3. Intuthuko

Ama-motor e-Axial flux abhekene nezinselele ezinkulu ekuklanyweni nasekukhiqizweni, naphezu kwezinzuzo zawo zobuchwepheshe, izindleko zawo ziphakeme kakhulu kunezama-motor e-radial. Abantu banolwazi oluphelele ngama-motor e-radial, futhi izindlela zokukhiqiza kanye nemishini yemishini nazo zitholakala kalula.

Enye yezinselele ezinkulu zama-axial flux motors ukugcina igebe lomoya elifanayo phakathi kwe-rotor ne-stator, njengoba amandla kazibuthe makhulu kakhulu kunalawo ama-radial motors, okwenza kube nzima ukugcina igebe lomoya elifanayo. I-dual rotor axial flux motor nayo inezinkinga zokushabalalisa ukushisa, njengoba ukugoqa kutholakala ngaphakathi kwe-stator naphakathi kwama-rotor disc amabili, okwenza ukushabalalisa ukushisa kube nzima kakhulu.

Ama-Axial flux motor nawo kunzima ukuwakha ngezizathu eziningi. Umshini we-dual rotor osebenzisa umshini we-dual rotor one-topology yama-yokes (okungukuthi ukususa i-iron joke ku-stator kodwa ugcine amazinyo ensimbi) unqoba ezinye zalezi zinkinga ngaphandle kokwandisa ububanzi be-motor kanye ne-magnet.

Kodwa-ke, ukususa ijoka kuletha izinselele ezintsha, njengokuthi ungalungisa kanjani futhi ubeke kanjani amazinyo ngamanye ngaphandle kokuxhumana kwejoka ngomshini. Ukupholisa nakho kuyinselele enkulu.

Kunzima futhi ukukhiqiza i-rotor nokugcina igebe lomoya, njengoba i-rotor disc idonsela i-rotor. Inzuzo ukuthi ama-rotor disc axhunywe ngqo ngendandatho yomgodi, ngakho-ke amandla ayahlukana. Lokhu kusho ukuthi i-intender bearing ayimelani nala mandla, futhi umsebenzi wayo kuphela ukugcina i-stator isendaweni ephakathi kwama-rotor disc amabili.

Ama-motor e-double stator single rotor awabhekene nezinselele zama-motor ayindilinga, kodwa ukwakheka kwe-stator kuyinkimbinkimbi kakhulu futhi kunzima ukukufeza ukuzenzekela, futhi izindleko ezihlobene nazo ziphakeme. Ngokungafani nanoma iyiphi i-radial flux motor yendabuko, izinqubo zokukhiqiza ama-axial motor kanye nemishini yemishini zisanda kuvela.

4. Ukusetshenziswa kwezimoto zikagesi

Ukuthembeka kubalulekile embonini yezimoto, futhi kufakazela ukuthembeka nokuqina kwezinhlobo ezahlukene zezimoto.ama-motor e-axial fluxukukholisa abakhiqizi ukuthi la ma-motor afanele ukukhiqizwa ngobuningi bekulokhu kuyinselele. Lokhu kuye kwashukumisela abahlinzeki be-axial motor ukuthi benze izinhlelo zokuqinisekisa ezibanzi ngokwabo, lapho umhlinzeki ngamunye ebonisa ukuthi ukuthembeka kwe-motor yabo akufani neze nama-radial flux motors avamile.

Ingxenye eyodwa kuphela engaguga ku-imoto yokujikeleza kwe-axialyi-bearings. Ubude be-axial magnetic flux bufushane kakhulu, futhi indawo yama-bearings iseduze, ngokuvamile yakhelwe ukuba "ilinganiswe kakhulu". Ngenhlanhla, i-axial flux motor inesisindo esincane se-rotor futhi ingamelana nemithwalo ephansi ye-rotor dynamic shaft. Ngakho-ke, amandla angempela asetshenziswa kuma-bearings mancane kakhulu kunalawo e-radial flux motor.

I-axle kagesi ingenye yezindlela zokuqala zokusebenzisa ama-axial motors. Ububanzi obuncane bungahlanganisa imoto kanye ne-gearbox ku-axle. Ezindleleni zokusebenzisa ezihlanganisiwe, ubude obufushane be-axial yemoto bufinyeza ubude obuphelele besistimu yokudlulisa.

Isinyathelo esilandelayo ukufaka i-axial motor esondweni. Ngale ndlela, amandla angadluliselwa ngqo kusuka ku-motor kuya emasondweni, kuthuthukiswe ukusebenza kahle kwe-motor. Ngenxa yokususwa kwama-transmission, ama-differentials, nama-driveshaft, ubunzima besistimu nabo buncishisiwe.

Kodwa-ke, kubonakala sengathi ukucushwa okujwayelekile akukaveli. Umenzi ngamunye wemishini yokuqala ucwaninga ukucushwa okuthile, njengoba ubukhulu obuhlukene kanye nokwakheka kwama-axial motors kungashintsha ukwakheka kwezimoto zikagesi. Uma kuqhathaniswa nama-radial motors, ama-axial motors anamandla aphezulu, okusho ukuthi ama-axial motors amancane angasetshenziswa. Lokhu kunikeza izinketho ezintsha zokuklama zamapulatifomu ezimoto, njengokubekwa kwamabhethri.

4.1 Ingalo ehlukaniswe ngezigaba

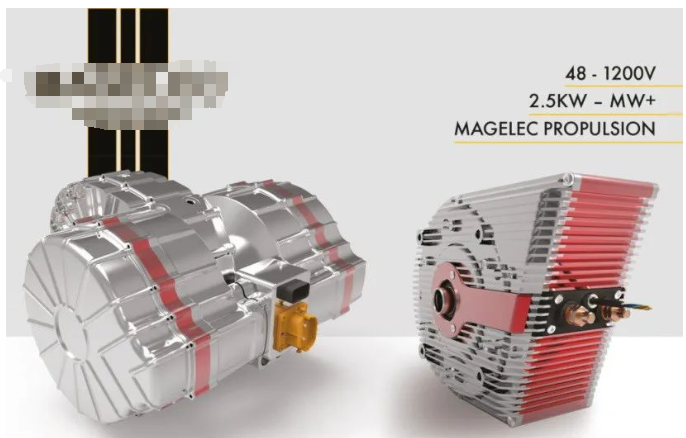

I-topology yemoto ye-YASA (Yokeless and Segmented Armature) iyisibonelo se-topology ye-single stator ye-rotor eyodwa, enciphisa ubunzima bokukhiqiza futhi ifanele ukukhiqizwa ngobuningi okuzenzakalelayo. Lawa ma-motor anamandla afinyelela ku-10 kW/kg ngesivinini esingu-2000 kuya ku-9000 rpm.

Isebenzisa isilawuli esizinikele, ingahlinzeka ngogesi ongu-200 kVA wemoto. Isilawuli sinomthamo ongaba amalitha ama-5 futhi sinesisindo esingu-5.8 kilogram, okuhlanganisa nokuphathwa kokushisa ngokupholisa uwoyela we-dielectric, ofanele ama-axial flux motors kanye nama-induction kanye nama-radial flux motors.

Lokhu kuvumela abakhiqizi bemishini yokuqala yezimoto zikagesi kanye nabathuthukisi bezinga lokuqala ukuthi bakhethe injini efanele ngokuguquguqukayo ngokusekelwe kuhlelo lokusebenza kanye nendawo etholakalayo. Usayizi omncane kanye nesisindo kwenza imoto ibe lula futhi ibe namabhethri amaningi, ngaleyo ndlela kwandiswe umfutho webanga.

5. Ukusetshenziswa kwezithuthuthu zikagesi

Kumabhayisikili kagesi nama-ATV, ezinye izinkampani ziye zakha ama-motor e-AC axial flux. Umklamo ovame ukusetshenziswa kulolu hlobo lwemoto yimiklamo ye-DC brush axial flux, kuyilapho umkhiqizo omusha uyidizayini ye-AC, engenamabhulashi evalwe ngokuphelele.

Amakhoyili womabili ama-motor e-DC kanye ne-AC ahlala engashintshi, kodwa ama-rotor amabili asebenzisa omazibuthe abangapheli esikhundleni sezinsimbi ezijikelezayo. Inzuzo yale ndlela ukuthi ayidingi ukuhlehliswa ngomshini.

Umklamo we-AC axial ungasebenzisa nezilawuli zezimoto ze-AC ezijwayelekile zezigaba ezintathu zama-radial motors. Lokhu kusiza ukunciphisa izindleko, njengoba isilawuli silawula ugesi we-torque, hhayi isivinini. Isilawuli sidinga imvamisa engu-12 kHz noma ngaphezulu, okuyimvamisa evamile yamadivayisi anjalo.

Imvamisa ephezulu ivela ekungeneni okuphansi kokujikeleza okungu-20 µ H. Imvamisa ingalawula ugesi ukuze inciphise ukugeleza kogesi futhi iqinisekise ukuthi isignali ye-sinusoidal ibushelelezi ngangokunokwenzeka. Kusukela embonweni oguquguqukayo, lena yindlela enhle yokufeza ukulawulwa kwenjini okubushelelezi ngokuvumela izinguquko ze-torque esheshayo.

Lo mklamo usebenzisa ukugoqa okusatshalaliswa kabili, ngakho-ke ukugeleza kukazibuthe kugeleza kusuka ku-rotor kuya kwenye i-rotor nge-stator, ngendlela emfushane kakhulu kanye nokusebenza kahle okuphezulu.

Isihluthulelo salo mklamo ukuthi ingasebenza nge-voltage ephezulu engu-60 V futhi ayifaneleki ezinhlelweni ze-voltage ephezulu. Ngakho-ke, ingasetshenziswa ezithuthuthu zikagesi kanye nezimoto ezine-wheels ezine ze-L7e njenge-Renault Twizy.

I-voltage ephezulu engu-60 V ivumela injini ukuthi ihlanganiswe nezinhlelo zikagesi ezijwayelekile ezingu-48 V futhi yenza kube lula umsebenzi wokulungisa.

Imininingwane yesithuthuthu esinezinqola ezine i-L7e ku-European Framework Regulation 2002/24/EC ibeka ukuthi isisindo sezimoto ezisetshenziselwa ukuthutha izimpahla asidluli amakhilogremu angu-600, ngaphandle kwesisindo samabhethri. Lezi zimoto zivunyelwe ukuthwala abagibeli abangaphezu kwamakhilogremu angu-200, imithwalo engaphezu kwamakhilogremu angu-1000, kanye namandla enjini angaphezu kwamakhilogremu angu-15. Indlela yokugoqa esabalalisiwe inganikeza i-torque engu-75-100 Nm, enamandla okukhipha aphezulu angu-20-25 kW kanye namandla aqhubekayo angu-15 kW.

Inselele yokujikeleza kwe-axial itholakala endleleni ama-copper windings aqeda ngayo ukushisa, okuyinto enzima ngoba ukushisa kumele kudlule ku-rotor. Ukugoqa okusabalalisiwe kuyisihluthulelo sokuxazulula le nkinga, njengoba kunenqwaba yezikhala zezingodo. Ngale ndlela, kunendawo enkulu phakathi kwe-copper negobolondo, futhi ukushisa kungadluliselwa ngaphandle futhi kukhishwe uhlelo olujwayelekile lokupholisa uketshezi.

Izigxobo eziningi zikagesi ziyisihluthulelo sokusebenzisa amafomu wamagagasi e-sinusoidal, okusiza ukunciphisa ama-harmonics. La ma-harmonics abonakala njengokushisa kwama-magnets kanye ne-core, kuyilapho izingxenye zethusi zingenakukwazi ukuthwala ukushisa. Lapho ukushisa kuqongelela kuma-magnets kanye nama-cores ensimbi, ukusebenza kahle kuncipha, yingakho ukwenza ngcono i-waveform kanye nendlela yokushisa kubalulekile ekusebenzeni kwemoto.

Umklamo wemoto wenziwe ngcono ukuze kuncishiswe izindleko futhi kufezwe ukukhiqizwa kwesisindo okuzenzakalelayo. Indandatho yendlu ekhishwe ngaphandle ayidingi ukucutshungulwa okuyinkimbinkimbi kwemishini futhi inganciphisa izindleko zezinto zokwakha. Ikhoyili ingalinyazwa ngqo futhi inqubo yokubopha isetshenziswe ngesikhathi senqubo yokugoqa ukuze kulondolozwe ukuma okufanele kokuhlanganiswa.

Iphuzu elibalulekile ukuthi ikhoyili yenziwe ngocingo olujwayelekile olutholakala kwezentengiselwano, kuyilapho umongo wensimbi ufakwe insimbi ye-transformer ejwayelekile ebekwe eshalofini, edinga nje ukunqunywa ibe yisimo. Eminye imiklamo yezimoto idinga ukusetshenziswa kwezinto ezithambile ezisebenzisa amandla kagesi ekufakweni komongo, okungase kubize kakhulu.

Ukusetshenziswa kwama-windings asakazwe kusho ukuthi insimbi yamagnetic akudingeki ihlukaniswe; Zingaba yizimo ezilula futhi kube lula ukuzikhiqiza. Ukunciphisa usayizi wensimbi yamagnetic nokuqinisekisa ukuthi kulula ukuyikhiqiza kunomthelela omkhulu ekunciphiseni izindleko.

Umklamo wale moto ye-axial flux ungenziwa ngokwezifiso ngokwezidingo zamakhasimende. Amakhasimende anezinguqulo ezenziwe ngokwezifiso eziklanyelwe umklamo oyisisekelo. Bese kwenziwa emgqeni wokukhiqiza wokuhlola ukuze kuqinisekiswe ukukhiqiza kusenesikhathi, okungaphindaphindwa kwezinye izimboni.

Ukwenza ngokwezifiso kungenxa yokuthi ukusebenza kwemoto akuxhomekile kuphela ekwakhiweni kwenjini ye-axial magnetic flux, kodwa futhi nasekhwalithini yesakhiwo semoto, ibhethri, kanye ne-BMS.

Isikhathi sokuthunyelwe: Septhemba-28-2023